Digital networks can communicate with real-world events thanks to the convergence of…

30+ Years of Automation Excellence

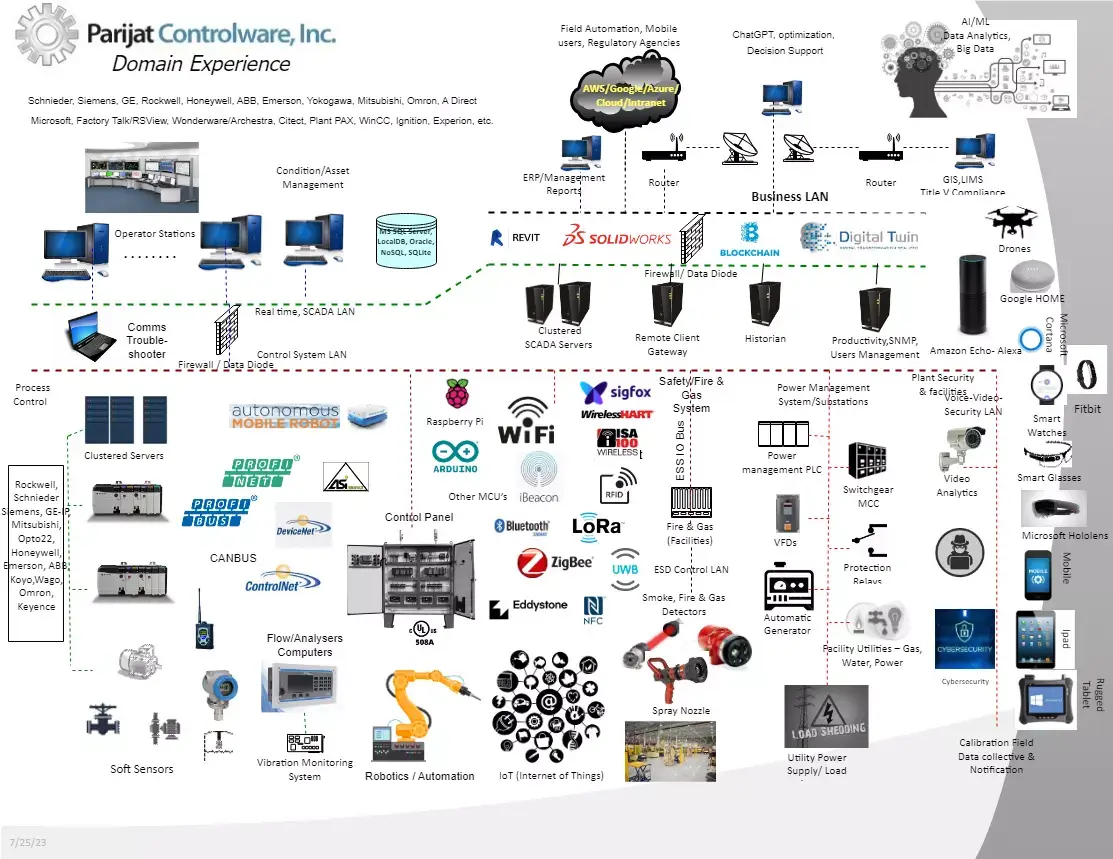

Parijat Controlware Inc.Parijat Controlware Inc. was established in 1989 with the aim of focusing on solutions for PAC, PLC, DCS, automation in engineering, process industries and development of Microsoft HMI/SCADA, non-Microsoft 3rd party HMI/SCADA. For the last several years, PCI is developing for MS products, RDBMS, AI/ML, data analytics, Big data, Digital Twins, Blockchain, tracking, manufacturing intelligence, and IoT Digitalization fault detection & many other areas. PCI has the world’s largest collection of communications drivers for Microsoft, Google, Apple products on one end & various smart industrial devices, like PLCs, VFDs, scales, flow computers etc. on the other end.

Parijat Controlware Inc. was established in 1989 with the aim of focusing on solutions for PAC, PLC, DCS, automation in engineering, process industries and development of Microsoft HMI/SCADA, non-Microsoft 3rd party HMI/SCADA. For the last several years, PCI is developing for MS products, RDBMS, AI/ML, data analytics, Big data, Digital Twins, Blockchain, tracking, manufacturing intelligence, and IoT Digitalization fault detection & many other areas. PCI has the world’s largest collection of communications drivers for Microsoft, Google, Apple products on one end & various smart industrial devices, like PLCs, VFDs, scales, flow computers etc. on the other end.

Parijat's Domain Expertise

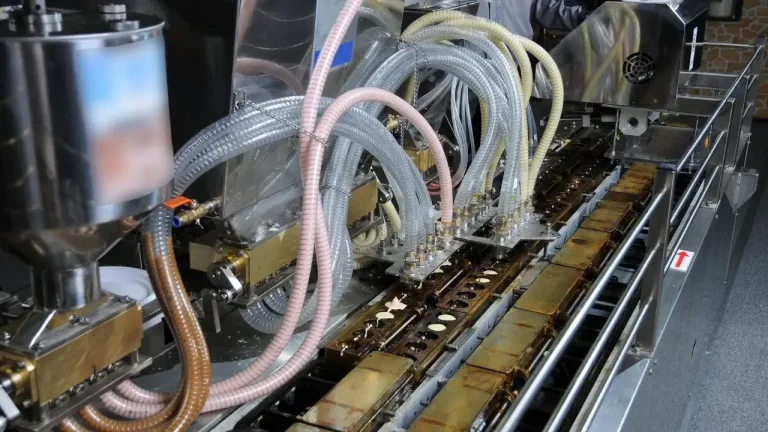

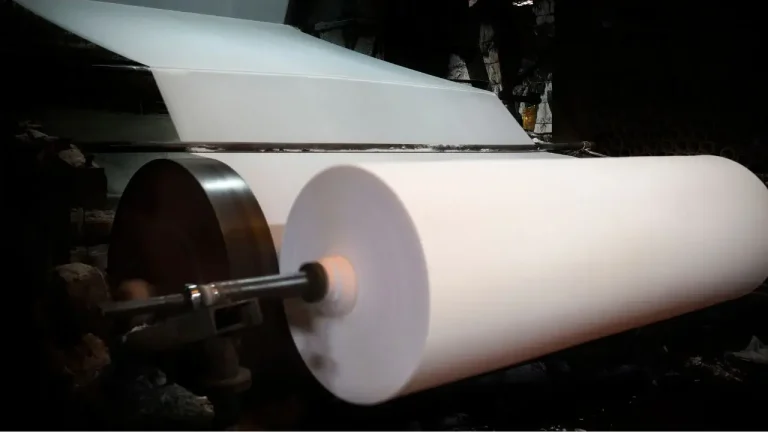

Our Recent Work Gallery

Our Gallery

Explore our recent projects

Our Happy Clients

Exploring Industry Trends

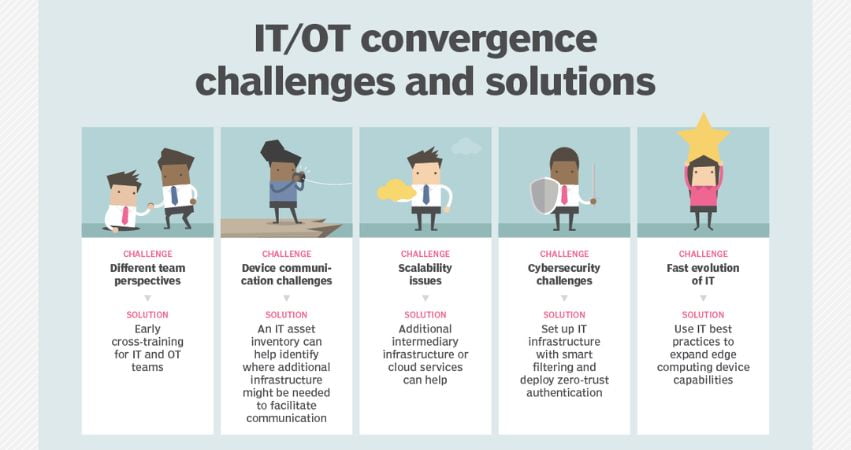

The proliferation of distributed, decentralized governance structures in large operational technology (OT)…

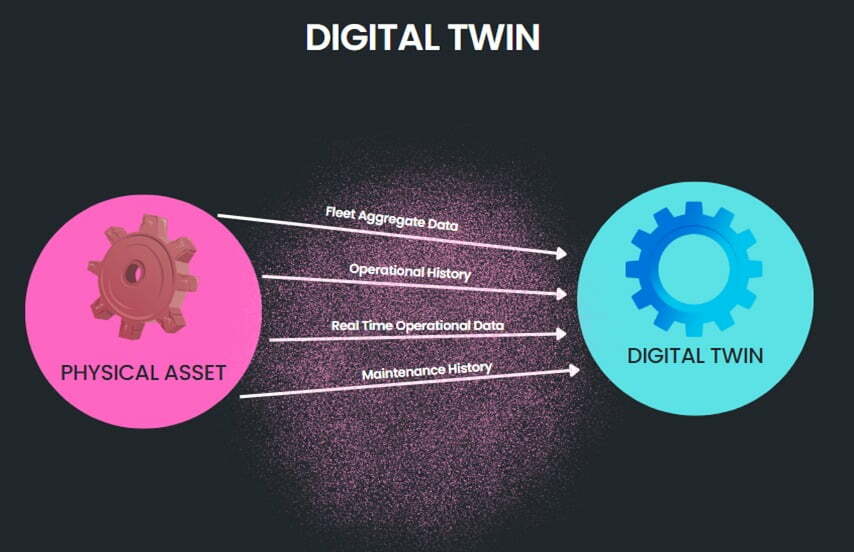

Digital twins are digital replicas of physical assets that allow for improved…

Our Story in Numbers

1000

+Projects Done

35

+Years Experience

200

+Happy Clients

300

+