The food and beverage industry is currently undergoing a significant transformation due to continuous innovation and technological advancements. The adoption of industrial control automation has revolutionized operations, leading to unprecedented efficiency and productivity in food processing and manufacturing. Automation technologies like Programmable Logic Controllers (PLCs), Distributed Control Systems (DCS), Supervisory Control and Data Acquisition (SCADA), and Human-Machine Interfaces (HMIs) have become the industry’s backbone. This transformation is particularly notable in the state of Texas, where Parijat controlware with over 30 years of automation excellence are leading the way in automating food and beverage plants.

Enhancing Efficiency and Productivity through Industrial Automation

Efficiency and productivity are key factors in the highly competitive food and beverage industry. Industrial control automation plays a pivotal role in optimizing these aspects throughout the entire value chain of food manufacturing. By leveraging state-of-the-art automation technologies, manufacturers can achieve significant improvements in operational efficiency and production output.

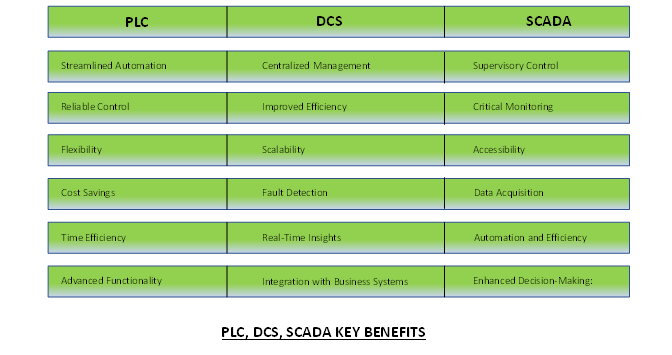

Programmable Logic Controllers (PLCs) form the heart of industrial control automation systems, providing precise control over various manufacturing processes. PLCs enable the automation of repetitive tasks, eliminating the need for manual intervention and reducing human errors. This leads to increased throughput, reduced cycle times, and enhanced overall productivity.

Distributed Control Systems (DCS) are widely employed in large-scale food processing plants to monitor and control multiple interconnected processes. DCS allows for centralized control and monitoring of various subsystems, enabling seamless integration and coordination across the production line. By consolidating data from multiple sources, DCS facilitates data-driven decision-making, further enhancing operational efficiency.

Supervisory Control and Data Acquisition (SCADA) systems provide real-time visibility and control over industrial processes. SCADA combines data acquisition, data presentation, and process control to enable effective monitoring and management of critical parameters. This enables plant operators to identify bottlenecks, optimize process variables, and respond promptly to any deviations, resulting in improved efficiency and reduced downtime.

Human-Machine Interfaces (HMIs) serve as the interface between human operators and industrial automation systems. These user-friendly graphical interfaces provide intuitive control and monitoring capabilities, empowering operators to interact with the production line efficiently. HMIs display real-time data, alarms, and trends, facilitating quick decision-making and troubleshooting. With enhanced visibility and control, operators can identify and resolve issues promptly, minimizing production disruptions and maximizing productivity.

Incorporating industrial control automation systems brings numerous benefits to food and beverage manufacturers. It streamlines production processes, reduces manual labour, and minimizes errors, thereby improving overall efficiency. With automated data collection and analysis, manufacturers gain valuable insights into process performance, enabling continuous improvement initiatives and optimization. Industrial automation also enables the integration of data from various stages of the production line, facilitating seamless coordination and resource utilization.

Ensuring Quality Control in Food Production

Maintaining uncompromising product quality is of paramount importance in the food and beverage industry. Industrial control automation solutions excel in this realm, ensuring consistency, traceability, and adherence to stringent quality standards.

Automation systems enable precise monitoring and control of critical parameters throughout the production process, from raw material handling to final product packaging. PLCs, with their precise control capabilities, ensure accurate ingredient proportioning, recipe management, and process control. By automating these critical aspects, manufacturers can achieve consistent product quality, minimize variations, and reduce the risk of human errors. Any deviations can trigger alerts, enabling operators to take corrective actions promptly and prevent the production of non-conforming products. Furthermore, automation systems facilitate comprehensive traceability, enabling manufacturers to track and record data about each batch or lot, including ingredients used, processing conditions, and quality test results. This traceability not only ensures compliance with regulatory requirements but also enables effective recall management in the event of product quality issues.

Industrial control automation also plays a crucial role in supporting quality assurance protocols, such as Hazard Analysis and Critical Control Points (HACCP). Automation systems help monitor critical control points, implement preventive measures, and maintain detailed records to ensure food safety and prevent contamination risks.

By implementing industrial control automation solutions, food and beverage manufacturers can not only meet regulatory requirements but also exceed customer expectations for high-quality products. The automation-driven quality control processes ensure uniformity, safety, and reliability, enhancing customer satisfaction and strengthening brand reputation.

Streamlining Packaging Processes with Automation

Packaging plays a critical role in the food and beverage industry, protecting products, enhancing shelf appeal, and providing essential information to consumers. Industrial control automation has revolutionized packaging processes, enabling manufacturers to achieve remarkable accuracy, efficiency, and consistency in their packaging operations. Automated packaging systems leverage advanced technologies such as robotics, vision systems, and high-speed conveyors to streamline packaging processes. These systems can handle a wide range of packaging formats, including bottles, cans, pouches, and cartons, with minimal changeover time.

Robotic packaging systems offer high precision and flexibility, allowing for precise product placement, accurate labelling, and efficient palletization. With their ability to handle delicate and fragile products, robots ensure product integrity and minimize product damage during the packaging process.

Vision systems integrated into automated packaging lines provide real-time quality inspection, ensuring that packaging materials meet the required standards. These systems can detect defects, such as improper seals, incorrect labels, or damaged packaging, and promptly reject faulty products, maintaining high quality and preventing customer dissatisfaction.

Furthermore, industrial control automation facilitates the synchronization of packaging line components, such as filling machines, capping machines, labelling machines, and conveyor systems, ensuring smooth and efficient operation. Automation systems control the timing, speed, and coordination of these components, reducing bottlenecks and optimizing overall line efficiency. Packaging automation also extends to secondary packaging processes, such as cartoning, case packing, and palletizing. These processes, traditionally labour-intensive, can be significantly streamlined and automated using advanced technologies. Automated carton erectors, case packers, and robotic palletizers ensure accurate and efficient packaging of products, reducing manual labour and minimizing errors.

Ensuring Safety and Compliance in Food Plants

Ensuring the safety of workers, consumers, and the environment is a top priority in the food and beverage industry. Industrial control automation plays a pivotal role in creating a safe and compliant production environment. Automation systems are equipped with built-in safety features, including emergency shutdown systems, safety interlocks, and alarms, to protect workers and prevent accidents. These features detect potentially hazardous conditions, such as equipment malfunctions, abnormal temperatures, or pressure deviations, and initiate immediate corrective actions or shutdown procedures to prevent harm.

Additionally, automation systems enable remote monitoring and control of critical process parameters, reducing the need for operators to physically interact with potentially hazardous equipment. This minimizes the risk of injuries and exposure to hazardous substances, creating a safer working environment for employees. Industrial control automation also facilitates compliance with regulatory requirements and industry standards. Automation systems can integrate process-specific safety protocols and ensure that processes adhere to predetermined safety parameters. This ensures that manufacturing operations comply with regulations such as the Food Safety Modernization Act (FSMA) and Good Manufacturing Practices (GMP).

Incorporating industrial control automation in food plants not only enhances safety and compliance but also improves operational efficiency. By proactively monitoring critical parameters and automating safety procedures, manufacturers can minimize downtime, reduce the risk of product recalls, and protect their reputation.

Driving Sustainability in the Food and Beverage Industry

Sustainability has become a core focus in the food and beverage industry, with increasing awareness of environmental impact and resource conservation. Industrial control automation contributes significantly to the industry’s sustainability goals by optimizing energy consumption, reducing waste, and enabling intelligent resource management. Automation systems enable precise control over energy-intensive processes, such as heating, cooling, and ventilation. By implementing energy-efficient control strategies and leveraging advanced algorithms, manufacturers can optimize energy usage and reduce overall consumption. This leads to significant cost savings and a reduced carbon footprint, contributing to a greener and more sustainable operation.

Industrial control automation also helps minimize waste generation through precise control of ingredients, materials, and packaging. By accurately proportioning ingredients and optimizing recipe management, manufacturers can minimize overruns, reduce material waste, and improve yield. Automated packaging systems ensure proper filling and sealing, reducing product loss due to packaging errors or leakage.

The integration of data analytics and machine learning capabilities in automation systems further enhances sustainability efforts. By analysing production data, manufacturers can identify inefficiencies, predict maintenance requirements, and optimize resource allocation. This data-driven approach enables continuous improvement initiatives, reduces resource consumption, and enhances overall operational sustainability.

Industrial control automation has emerged as a game-changer in the food and beverage industry, driving efficiency, quality control, safety, and sustainability. By leveraging automation technologies such as PLCs, DCS, SCADA, and HMIs, manufacturers can optimize production processes, ensure regulatory compliance, and enhance overall operational excellence. Parijat Controlware stands as a trusted partner, offering tailored industrial control automation solutions designed specifically to address the unique challenges and requirements of the food and beverage industry. With their expertise and cutting-edge solutions, manufacturers can embrace the transformative power of industrial control automation and thrive in an increasingly competitive landscape.