Introduction

The pharmaceutical industry is undergoing a paradigm shift, driven by the integration of advanced automation solutions and cutting-edge technologies. From robotics and machine learning to data analytics and control systems, the utilization of automation services has revolutionized manufacturing and supply chain processes, offering pharmaceutical companies unprecedented opportunities for increased efficiency, compliance, and productivity. This comprehensive article explores the pivotal role of automation services in the pharmaceutical sector and delves into the profound impact they have on companies operating within this dynamic and highly regulated industry.

Streamlining Manufacturing Processes with Robotics and Control Systems

Automation have significantly streamlined pharmaceutical manufacturing processes by harnessing the power of robotics and advanced control systems. Robotics, integrated with precision and sophistication, execute repetitive tasks with unparalleled accuracy, ensuring consistent product quality while minimizing the risk of human error. The seamless integration of control systems, such as Programmable Logic Controllers (PLCs) and Distributed Control Systems (DCS), empowers real-time monitoring and control, allowing for immediate adjustments and the optimization of production timelines while minimizing downtime.

Leveraging Data Analytics and Machine Learning for Quality Control

Pharmaceutical companies are leveraging automation services to implement cutting-edge quality control measures, driven by data analytics and machine learning. Real-time analysis of vast volumes of production data enables early detection of anomalies, empowering proactive measures to maintain high product quality and adherence to stringent regulatory standards. Additionally, automated systems equipped with machine learning algorithms perform in-line inspections, significantly reducing the need for manual sampling and improving overall manufacturing efficiency.

Optimizing Inventory Management through Automation

Automation plays a crucial role in optimizing inventory management for pharmaceutical companies. By leveraging enterprise resource planning (ERP) and warehouse management systems (WMS), companies gain real-time visibility and control over their inventory. Monitoring inventory levels, tracking expiration dates, and efficiently managing the supply chain become seamless processes, minimizing stockouts, reducing waste, and enhancing procurement operations. The result is improved cost savings, enhanced customer satisfaction, and a more streamlined supply chain.

Ensuring Regulatory Compliance with Automated Documentation

Compliance with stringent regulations and quality standards is paramount in the pharmaceutical industry, and automation services provide vital assistance in this area. Automated documentation systems facilitate accurate and traceable record-keeping throughout the manufacturing and distribution processes. By eliminating manual processes and human errors, companies can ensure regulatory compliance, reduce risks, and streamline regulatory audits. Integrating compliance checks into automated processes further enhances efficiency and ensures adherence to regulatory guidelines, providing companies with peace of mind.

Harnessing the Power of Automation for Advanced Research and Development

Beyond manufacturing and supply chain operations, automation services are transforming pharmaceutical research and development (R&D). Robotic systems and automation technologies enable high-throughput screening, accelerating the discovery of new drug candidates and optimizing the development process. Automation-assisted experiments and data analysis streamline R&D workflows, allowing scientists to focus on critical analysis and decision-making. This expedites the development of life-saving medications and fosters innovation within the pharmaceutical industry.

Driving Continuous Improvement through Predictive Maintenance

In addition to manufacturing and research, automation services provide pharmaceutical companies with the ability to implement predictive maintenance strategies. By leveraging machine learning algorithms and sensor-based monitoring systems, companies can detect potential equipment failures before they occur. This proactive approach reduces unplanned downtime, enhances equipment reliability, and improves overall operational efficiency. With predictive maintenance, pharmaceutical companies can optimize their maintenance schedules, reduce costs, and ensure continuous production.

Enhancing Supply Chain Visibility and Efficiency

Automation services have transformed supply chain management for pharmaceutical companies by providing real-time visibility and efficient tracking capabilities. By integrating supply chain management systems with automation technologies, companies can monitor inventory levels, track shipments, and anticipate demand fluctuations. This enables proactive decision-making, minimizing delays and ensuring timely deliveries. Automation-driven analytics provide insights into supply chain performance, enabling optimization of inventory levels and enhancing overall supply chain efficiency.

Conclusion

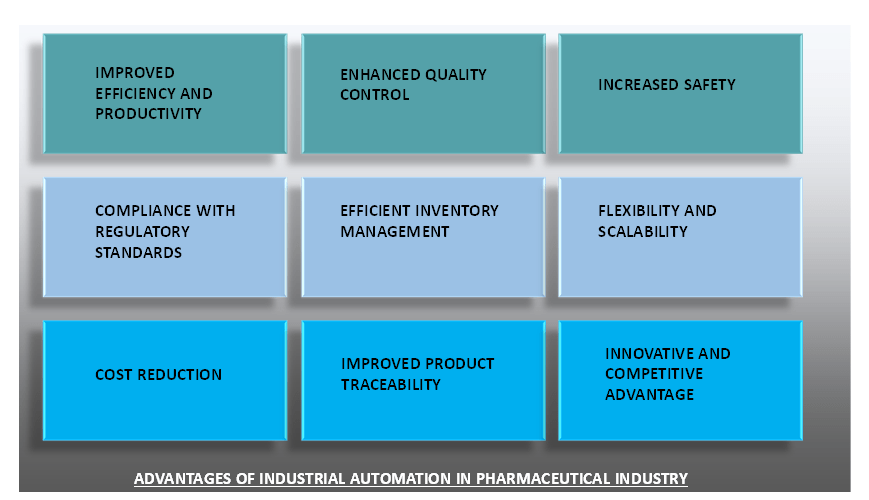

Automation services have become an indispensable catalyst for the transformation of the pharmaceutical industry. By leveraging cutting-edge technologies such as robotics, data analytics, control systems, and predictive maintenance, companies can streamline manufacturing processes, enhance quality control measures, optimize inventory management, drive continuous improvement, and improve supply chain visibility and efficiency. Moreover, automation is driving advancements in pharmaceutical research and development, paving the way for the discovery of new drugs, and improving patient outcomes.

In this realm of automation solutions, Parijat Controlware, Inc. stands as a leading provider of tailored automation services to the pharmaceutical industry. With their deep expertise and innovative solutions, Parijat Controlware, Inc. has helped numerous pharmaceutical companies optimize their processes, improve safety measures, and make data-driven decisions. Their comprehensive suite of automation services encompasses robotics integration, control system implementation, data analytics, predictive maintenance, and supply chain optimization.

Parijat Controlware, Inc. understands the unique challenges and regulatory requirements of the pharmaceutical industry, and they have consistently delivered customized automation solutions that meet the specific needs of their clients. Their commitment to excellence, reliability, and customer satisfaction has made them a trusted partner for pharmaceutical companies seeking to achieve operational excellence and drive sustainable growth.