Digital networks can communicate with real-world events thanks to the convergence of IT and OT. Both IT and OT, or operational and information technology, transmit information, store data, and constitute the basis of many company operations. To deliver results and a unified strategy to systems covering, Parijat Controlware. Inc. combines these two systems, allowing associations and diligence to communicate data obtained from OT operations to their digital IT networks.

IT systems are a component of data-centric computing. OT systems are used in industrial and business processes to cover, process, and adapt to events. A single system that integrates IT and OT allows for increased product( 3D visualization, cumulative manufacturing, and artificial robots), bettered process effectiveness ( intelligent control, traceability), and sustainability( prophetic analytics and data wisdom) in an artificial manufacturing installation

What’s IT (Information Technology)?

Information technology (IT) refers to the computer, networking, and data storage methods used to gather, manage, test, and transport data within and across organisations. IT’s ability to be programmed and reprogrammed to meet the needs of operations, networks, and end users is one of its key characteristics. Examples include both hardware, such as computers and networking equipment (such as switches, routers, firewalls, storehouse arrays, and backup bias), and software, which includes spreadsheet and database programmes as well as operating systems and client relationship management (CRM), business intelligence (BI), enterprise resource planning (ERP), and manufacturing prosecution systems (MES).

What’s OT (Operational Technology)?

OT (Operational Technology) includes computing, networking and storehouse technologies used to cover, process and relay information about and control physical processes in artificial workflows. OT is also comprised of tackle and software results but, unlike the nearly measureless possibilities offered by programmable IT, OT is frequently designed to execute a specific task, similar as examiner mechanical performance, control heat or detector exigency shutoffs. OT range from simple position tracking detectors to programmable Logic Controllers ( PLCs), distributed control systems( DCS), computer numerical control( CNC) systems, erecting robotization systems( BAS) and complex artificial control systems( ICS) including the administrative control and data accession( SCADA) systems used to collect, assay and collect outfit data similar as temperature, vibration and power operation — to regulate outfit in ways designed to maintain peak operation and effectiveness and minimize time-out.

What Are The Differences Between IT And OT?

IT (Information Technology) primary ideal is collecting and analysing information to induce mindfulness or regulate business processes, IT network is business acquainted which substantially deals with information rather than machines. IT includes different types of networks including transactional, voice, videotape, and big data. The IT network verifies the prejudice and users on the network to ensure security.. IT systems are generally suitable to perform essential operations within programmed functions without important mortal intervention. IT problems include sustaining infrastructure and protecting it from cybersecurity risks for infrastructure like IoT technology. While the main goal of operational technology (OT) is to gather and use information to manage the physical activities carried out by an organisation.

OT has traditionally needed for physical operation, controlling mechanical operations and Automating industrial equipments. OT evolved from the first digital control technologies designed to be directly integrated into ministry similar as PLCs, and as similar wasn’t designed to integrate with IT. OT and IT network structure have analogous rudiments, like switches, routers, and wireless technology. thus, OT networks can profit from the rigour and experience that IT has erected over the times with common network operation and security controls to make a solid network foundation. still, there are crucial differences in between both the networks

Formfactor

OT network are also capable to work in lower and modularized form factors so they can be mounted in different ways, similar as on rails, walls, or light poles, in buses , or indeed bedded within other outfit.

Hardening

OT network structure may need to be ruggedized when stationed in severe artificial conditions. The structure must be resistant to shock, vibration, water, extreme temperatures, and sharp air and chemicals.

Network Interfaces

Depending on their purpose, OT may support networks similar as WAN to connect artificial IoT( IIoT) bias.

Protocols

OT network bias connect IoT detectors and machines, which run dispatches protocols that aren’t generally used in traditional IT networks. thus, artificial networking products must support a wide variety of protocols similar as Modbus, Profinet, and Common Industrial Protocol (CIP).

IT/ OT In A Single System Or IT/ OT Convergence

For today’s data-driven manufacturing businesses, IT and OT convergence has become crucial to success. Manufacturing bottom control systems and business calculation systems are becoming more and more necessary in a variety of industries, including oil and gas, metals, packaging goods, pharmaceuticals, food, and alcoholic beverages. Business can work with IT experts to find the best solution for their unique circumstances and only invest in systems that will truly have an impact. Once systems are integrated into the point, businesses should easily define where liabilities lie across the various brigades who initially managed IT and OT. IT/OT Convergence is the newest and most effective solution for every Assiduity. Liabilities must be defined to eliminate any chance of misunderstanding or poor communication.

To enable organisations to improve processes in creative ways, Parijat Controlware. Inc is providing solutions to bring information technology and operations technology together to empower associations to ameliorate processes in different ways. While OT have the moxie and perceptivity to make nuanced opinions about how to manage outfit and keep processes running easily, IT/ OT Convergence enables OT professionals to predetermine conduct grounded on specific conditions, from cataloguing conservation grounded on a decline in performance due to a dangerous terrain. IT/ OT in a single system can transmit information to an operation from field outfit or detectors, which also passes instructions to an selector grounded on that information, automatically controlling outfit without the need for a mortal driver. While OT workers still oversee and manage this robotization, they no longer bear to manually cover every process and reply to every situation

Parijat Controlware. Inc is bridging the gap of IT/ OT communication through proper gateways to communicate OT system with IT systems and for this, we’ve a variety of instruments and detectors that can communicate over multiple communication protocols. IT/ OT integration in large scale diligence is about the capacity to freely manage Big Data. As technology is getting a commodity while operation designs and content are being produced, it’s doable to suppose about consolidating all data in a single case to explore and profit from new business scripts. Achieving a significantly high return is doable as the large investments in smart structure are formerly done in utmost cases and IT investments are veritably minimum in comparison.

Benefits Of IT/ OT Convergence

When IT/ OT integration in a single system is used, this integration empowers organisations to ameliorate their processes in many ways, which may increase productivity. Then are some of the crucial provocations for chancing openings for IT/ OT convergence.

1. Optimizing Processes

Companies that apply integration4.0 and IT/ OT confluence strategies can use system data to increase edge and streamline, automate and else optimize business and physical processes

2. Mitigating

Machine time-out and conservation IT OT in a single system is used to collect OT data and IT systems to assay that data allows drivers to legislate prophetic conservation strategies rather than precautionary and reactive conservation strategies, which drastically help unplanned time-out from dismembering diurnal operations and conservation costs., IT/ OT convergence systems can indeed enable drivers to conduct conservation work ever.

3. Generating New Service

Immolations and Revenue Aqueducts IT/ OT convergence can also allow OEMs to shift from dealing outfit to use them with newer technologies, which eliminates high outspoken outfit costs for guests and provides OEMs with predictable long- term profit.

4. Speed up response times

Monitoring OT systems independently of IT systems runs the threat of breakdowns in communication and dropped incident running between multiple departments.

Parijat Controlware Inc. Solutions Integrated IT/OT

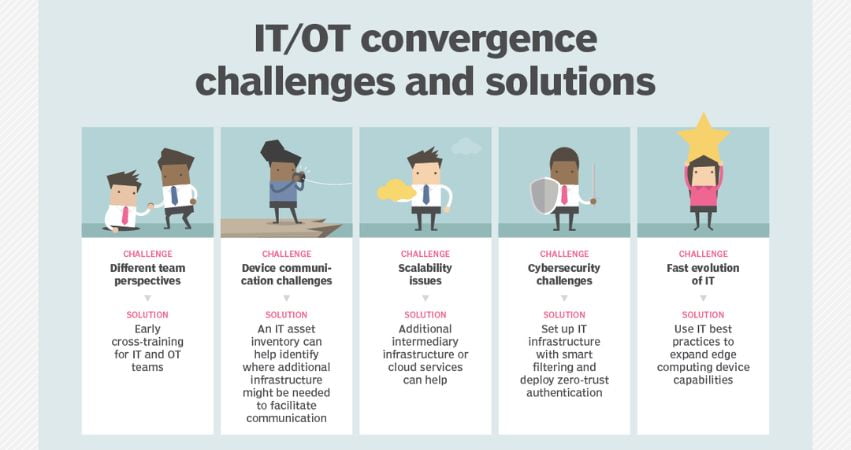

IT/OT users, installers, and operators confront difficulties with interoperability, equipment maintenance, and cybersecurity protection for equipment like Internet of Things technologies. IT systems have long been much more prone to cybersecurity risks since many OT systems have historically been closed. However, Parijat Controlware. Inc. is currently delivering results in IoT and IIoT bias that are less frequently connecting physical devices to the internet as well, and our cybersecurity result in conjunction with the IT/OT minimise the threat of cyber hazards. Companies interested in IT/OT confluence frequently encounter difficulties when attempting to connect their IT systems to their OT systems, in addition to cybersecurity challenges. Our Specialized Unit developed a single digital security and threat operation function to lessen threat in Convergence Technology. This department should report to IT but oversee all OT and IT security. To maintain a secure and safe communication ground between IT and OT, Parijat Controlware. Inc. offers a solution which outcomes with the deepest numerous layers of secured communication bias. For instance, it can be difficult to use IT to gather data from OT systems since OT outfit usually has different dispatching protocols than edge bias.It can be difficult for installers and drivers to connect edge bias to secure wireless networks and to optimise those connections for energy efficiency and data transfer, but Parijat Controlware, Inc. has multiple communication drives that can securely communicate with any bias using any communication protocol. Parijat Controlware, Inc. is delivering IT/OT results in a single system, including boosting efficiency, refining the customer experience, product robotization, and attaining manufacturing and force chain integration. Parijat Controlware. Inc has successfully implemented several IT/OT systems among our key systems, The aluminium extrusion industry is one of our key systems.

Belting Up

IT- OT integration might feel inviting. still, it’s an essential first step for any association that wants to realize the benefits of this convergence. While uniting two departments who have historically done their own thing comes with a whole range of challenges, benefits like streamlined processes, interoperability, and cooperative decision–making make IT- OT convergence extremely valuable.