Parijat Thermal/Video HotSpot Detection System NGSH-0732

Introduction:

Monitoring hotspots using a contactless thermal/IR, in conjunction with Video camera is a great method to catch problems early before they get serious. The usual method for performing spot checks on substation equipment involves handheld thermal imaging cameras. The substation equipment’s remote monitoring system includes multiple cameras and sensors mounted on a pan and tilted in various positions for visual, thermal, corona discharge, and intrusion detection. Parijat Thermal/Video Hotspot Detection system (PTHD) automatically scans the designated areas, locates any joints or potential hot spots, measures temperature, and prepares a report of the results, highlighting any hot spots found. The software application’s threshold configuration and other calculations are used to calculate the hotspot.

PRODUCT OVERVIEW

Keeping an eye on safety concerns in a substation, maritime, oil and gas environment, or refineries can be difficult, particularly when it comes to hotspot identification. PTHD Solutions from Parijat Controlware. Inc. solve these two crucial health, safety, and environmental (HSE) issues. PTHD hotspot detection in uncooled, real-time thermal and optical imaging offers benefits to the industry.

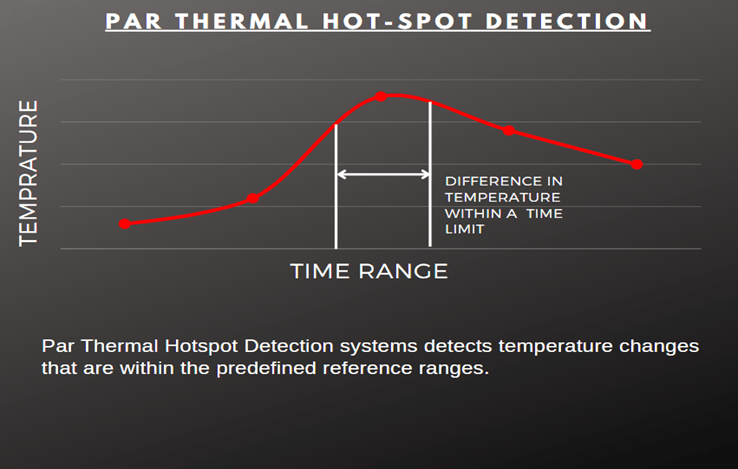

Parijat Controlware, Inc. developed a highly configurable PTHD system for locating hot spots, monitoring them, detecting fires, and keeping track of temperature (thermography) in substations and other places. Based on large temperature fluctuations, this device can automatically recognize potentially hazardous situations and take the necessary precautions. The threshold selected in the PTHD determines the hotspot.

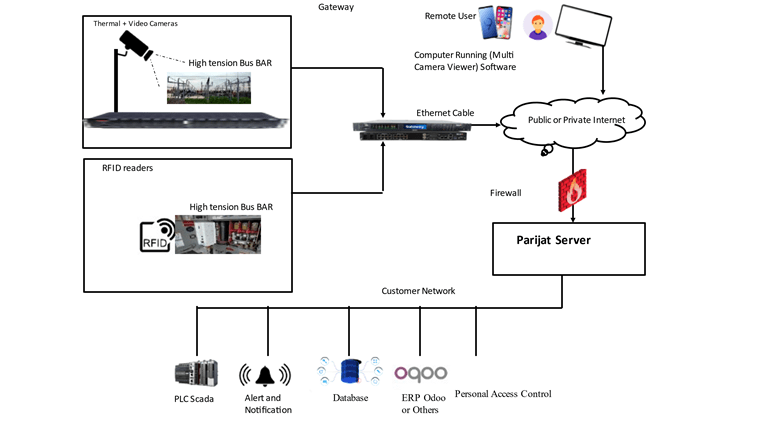

Data is gathered from the site over time and reviewed by PTHD to find patterns and abnormalities with continuous monitoring. Instead of single photograph in software, PTHD supports PTZ features for both thermal & video cameras. Thermal cameras can be connected directly with the industrial control platform, such as SCADA, PLC, DCS systems using over 200 PCI drivers. This results in:

- Good for electric ARC flash, Hotspot detection

- Create and manage scanning paths.

- Real-time monitoring of numerous assets

- Identify hotspots and changes in thermal heating rates.

- Data transmission and PTZ control of the camera

- Data and image interpretation Email data and image reporting Hot Spot Trending Analysis & report generation

The system monitors temperature differences in system components, which might trigger an alert and provide early warnings. As a result, automatic better maintenance planning and a lower danger of catastrophic failure is provided.

The figure shows a combination of use of our RFID based near area Hotspot monitoring system also.

What are the benefits of PTHD and Main Features?

PTHD automatically tracks the temperature development of each hotspot in circulation. It is easy to adapt to diverse industrial settings and operational modes because to its flexible structure and highly reliable components. These are the features of PTHD and its software.

PTHD system handles concurrent thermal and visual camera data collecting, processing, analysis, reporting, and data archiving. Depending on the size and location of the electric network and/or substations, the system can be stretched over multiple systems.

- Each tour stop can have emissivity, transmission, color palette, focus, NUC, and ROI configured

- Tools like the histogram, temperature trend, and line profile can be used for image analysis.

- Support for a variety of ROI shapes, including as points, lines, rectangles, ovals, free lines, broken lines, polygons, and rotated rectangles.

- Support for processing tools like Isotherm and dynamic hot spot identification possible.

- Instant Alarms and warnings based on user-defined crucial temperature values or ranges.

- Pre-trigger buffer for temperature-based critical image archiving.

- The ability to load site maps in a variety of graphic formats with camera settings.

- Reports on historical temperature trends in several widely used formats, sent email or SMS automatically based on user-defined events or schedule.

- An intuitive GUI for asset parameters and sensors

- Simple integration into current plant control systems or DCS protocols for data export

- Industry-standard analytics are integrated with automated analysis, which includes a historical database.

- Software may be hosted via the cloud or installed on a local server.

- Installation is non-invasive and comparatively painless.

- The automatic analysis may be supplemented with Advanced AI/ML analysis.

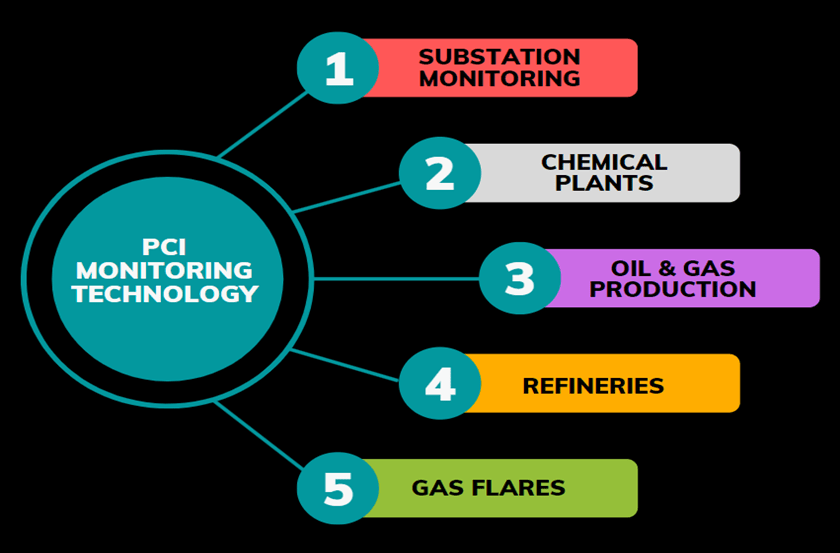

PCI TECHNOLOGY APPLICATION AREAS

Most firms require hot-spot thermal detection to maintain the operation protracted accuracy and safety. This is particularly important for sectors where hot spot temperature problems could occur. PCI Monitoring technology can be quite beneficial to a variety of industries like Energy, Metals etc as depicted in the image below.

- Installation is non-invasive and comparatively painless.

- Almost no longer requires manual examination.

- Maintenance costs go down, and worker security goes up.

- The automatic analysis may be supplemented with Advanced AI/ML analysis.

Some of the above features may require Hardware options & custom development.