Parijat RFID HotSpot Detection System (PRHD) NGSH-0706

Space for accommodating the additional equipment in the modern-day compact substation panels is very crucial, and Wireless Sensor based Detection Solution system is having a great advantage in monitoring of Substation (Indoor) Equipment. Monitoring hotspots using passive battery-less UHF RFID sensor Tags is a great method to catch problems before they become problematic. The advantages of Radio Frequency Identification (RFID) sensor tags include battery-free operation and cheap cost, making it ideal for long-term temperature monitoring in substations. They enable for the prevention and prediction of electrical equipment overheating (critical temperature >120°C) owing to overload, corrosion, loose connections, and challenging environmental conditions, as well as predictive maintenance of electrical insulation, whose lifespan is impacted by temperature. These hotspots might lead the substation to fail, causing plants that rely on the substation to shut down. It’s also possible that it’ll result in mishaps. To avoid such a breakdown or catastrophe, it is critical to monitor “hot spots” in a substation on a frequent basis.

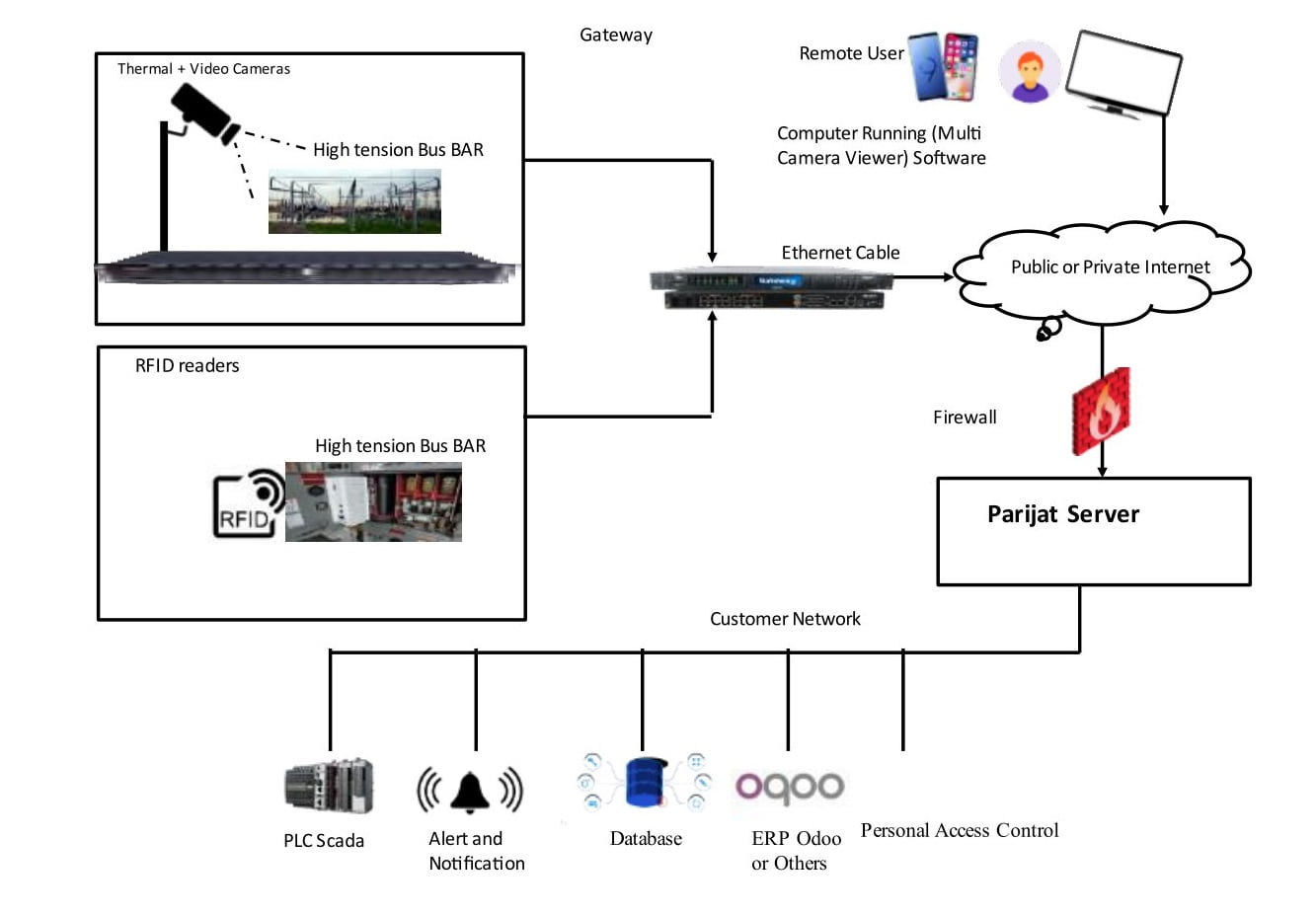

The figure shows a combination of use of our Thermal/Video camera based wider area Hotspot monitoring system as well.

PCI has developed a purpose-built tailored solution PRHD based on the inexpensive sensor Tags that is excellent for monitoring hot spots and temperature swings in Substations and other areas where hot-spot recognition from low distances is critical & desirable. PRHD can identify different range of temperatures and associated potentially dangerous circumstances and help take necessary precautions based on temperature variations. The hotspot is determined by the threshold set in PRHD. Passive Wireless Temperature Sensors (Battery less) will be suitable for mounting direct on live installation up-to 33 KV systems or higher. The antenna is installed inside the breaker cubicle and cable chamber or near proximity for interrogating the sensors for detection of temperature. The remote monitoring unit/ Reader/ receiver connect in between antennas and the Data Acquisition cum configuration System.

PRHD is designed to take the temperature readings regularly of all possible hot-spot sites (often junctions between components in a switchyard/substation). If it surpasses the threshold, it is classified as a hot spot, and a report/alarm is generated.

PRHD is often installed and monitored in the Switchyard’s Control Room. If any hot spots are discovered, they are carefully verified, and their status is updated. Any hotspot site may be graphed against time/dates to detect an increasing pattern, which aids in analysis and preventative maintenance.

Data is collected over time at a near distance from the location and analysed by PRHD to detect patterns and irregularities with continuous monitoring.

APPLICATIONS

- Switchgears for medium-voltage electrical systems

- Switching station / E-House

- Cabins for transformation

- Substations on wheels

- Solar power systems

- Wind turbines

- Systems for electricity generation and distribution

Features

- First and for most important safety feature of the solution is it avoids the prospect of damage to the equipment and humans in quite earlier stage by detecting the formation of

- Identify transient thermal event which were not detectable with manual inspections and hence prone to manual error.

- Provides quantitative temperature readout and remote visual monitoring for plant management

- Reduced maintenance costs and enhanced personnel

- Sensor are battery less and

- Accuracy of measurement system is ±5 degree C or

- Sensor used are calibration free devices hence durable over Longer

- The size of sensors is suitable to be installed in switchgear without compromising any clearances as per relevant IEC/IS

- Remotely monitor multiple, substations from a central location

- Improved reliability of electric power delivery by reducing the risk of breakdowns such as blackouts, brownouts, and the service requirement shall be turned into planned preventive maintenance.

- Some customers report an insurance premium discount because of the increased reliability

Example Areas of Substation components monitored

Circuit breaker arms / Bus bar joints at breaker ends, Bus bar turnings or extension joints, Cable termination at the end of switchgear.

Some of the above features may require Hardware options & custom development