Hand, Manual Valves & unwired process data Management Solution

Introduction

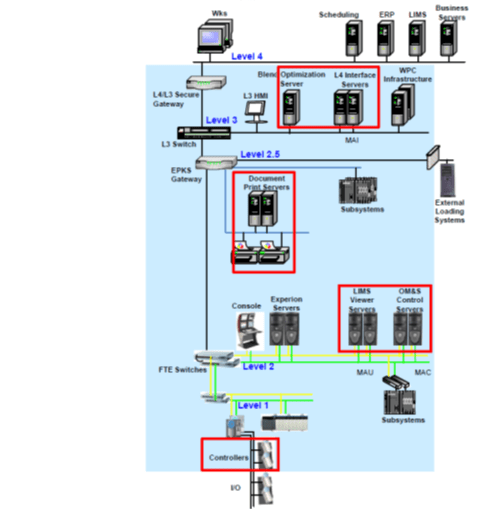

Parijat Controlware, Inc. (PCI) solves the problem of dealing with manual, hand valves position & also the ability to read process data like temperature, humidity, pressure, position, vibration, light, acceleration etc, from locations where there are no wires, power wiring or it is economically prohibitive. The Solution results include reduced product cost and faster time to cash, increasing customer satisfaction. Intrinsically safe versions of the sensors are also available. The sensors may be powered or use battery power that may last up to 1 year. Routers may be placed strategically to cover a wide range of geographical areas. The routers need power & may work wirelessly on the other side. Wi-Fi, Zigbee, wirelessHart & different types of technologies are supported.

- The solution is particularly designed to operate in plants where full automation of all pumps and valves does not exist

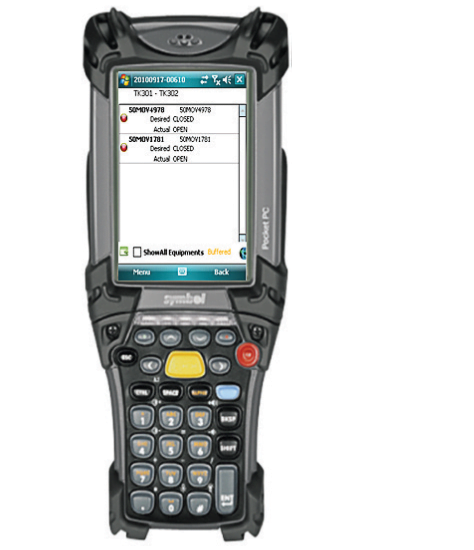

- Intrinsically safe or regular mobile iPads, Androids, or Microsoft Surface units may be used for field personnel collaboration or telepresence applications with the control room & other subject matter experts. They all access the same central data pool to avoid any traditional human error-prone activities. SOP, user manuals, drawings any other required documents, maintenance management, work orders & equipment discrepancies from desired states are available. iBeacon, Eddystone etc. are supported to ensure synchronized data updates globally for workflow procedure execution, event tracking, validation, manual data collection.

What Problems Does It Solve?

Users can harness, mine data and information from across the enterprise about the solution (via any desired means like desktops, mobile devices, browsers etc.) to achieve major improvements in the operation, including:

- Monitor & track the valves that do not have positioners wired into a control system. Solution can provide the % open or close state.

- Can measure vibration of any surface.

- Can measure ambient temperature & also the temperature of surfaces away from the sensor.

- Ambient humidity, pressure & light condition

- Can measure position, movement & acceleration.

- Can provide ‘identification’ for the equipment

- Automatic synching of manual data with server (both directions) when the handheld comes in the vicinity of a trusted wireless network.

- Control of the 2 state devices may also be effected.

- Possible uses in Process plants, and distribution centers, with multiple users working simultaneously.

- Standardized, simplified workflow processes – dynamically reallocate assets, and resources to suit your daily changing requirements.

- Optimized preventive maintenance, powerful system & hardware diagnostics

- Any missing or desirable features will be added on request.

Traditional solution slide: MS Excel worksheets, Scada, plant control system, manual data collection, work orders, maintenance management, documentation management, historian.

All of PCI employees are H2S and Land Safety Trained & have completed the IDAC HSE Rig pass course which includes SafeGulf and SafeLand