Introduction

Parijat Controlware Inc. (PCI) has been in business since 1989, serving any manufacturing, oil & gas, etc. supply chain management projects worldwide. PCI initially built its reputation on the ability to provide quality and extremely reliable control and safety systems for the oil and gas industry. PCI has successfully completed projects for several end users, in various industries. PCI forte is programming & diagnosing PLCs, HMI/SCADA systems & related business, and enterprise applications solutions.

PCI designs/builds end-to-end turn-key automation control system solutions from field devices to mobile devices to the top end of enterprise applications, including order fulfillment. PCI adopts a wide range of controllers like Rockwell/Allen-Bradley, Siemens, ABB, Schneider, Emerson/GE, Honeywell, Automation Direct, Opto22, Mitsubishi, Omron, Toshiba, etc. PCI also has a private label PLC of its own designed for almost 10000 ft depth of ocean floor with components exposed to full depth pressure. PCI uses Microsoft Visual Studio .NET technology for HMI/SCADA or products Like Rockwell – PlantPax, FT/RSView/Panelview; Schneider/Aveva – Wonderware, Archestra, Indusoft, Geo/ClearScada, Citect, Telvent; Siemens – WinCC, TIA, OA; Emerson/GE – Proficy, iFix, Simplicity; Mitsubishi Iconics, Inductive Automation, etc. A client has the choice to pick what precise combination to use. Best features & economies are achievable from Microsoft & Rockwell combination. Solutions are neutral or agnostic to the control systems hardware, networking & all other related peripheral control equipment.

PCI’s own products always use contemporary technologies. The database of choice is the latest version of MS SQL Server or Postgres. Only a single copy of data is employed from end to end. Products may be further customized to nth degree of the client’s needs. Virtualized, cloud & locally hosted servers are fully supported.

PCI PLC Infrastructure

Additional features available when Parijat PLC program Infrastructure is employed.

- Online relevant PLC code viewable in HMI

- Built-in simulation and override capability that may be invoked anytime for testing, training, troubleshooting or get around failed equipment/hardware etc.

- Extremely powerful control diagnostics – ask for more details

- Simplified single step MOC (management of change)

- Live integrated drawings, user manuals, etc.

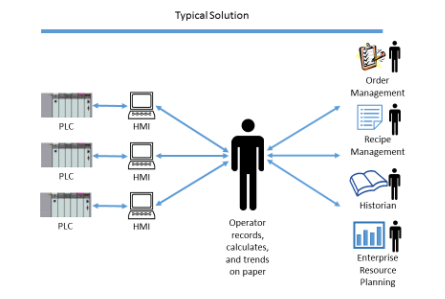

Traditional, Typical Solutions

Typically, system solutions use multiple products from different vendors, running on Microsoft Windows. This results in a heterogeneous solution with multiple copies of data & multiple dependencies on non-Microsoft vendors. Also, there are vulnerabilities to human data entry errors.

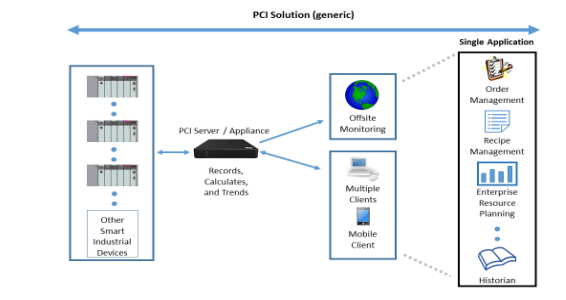

PCI Solutions

PCI solution integrates all of above layers into a single Parijat product management System with a single copy of data. However, if there are adequate technical reasons in the project in question, then the solution may be broken out also into desired islands, maintains data integrity & avoids human errors.

Other Options

- Use your choice of control systems HW, smart field devices or any HMI/SCADA system. If one does not exist, we shall provide one.

- support 360 deg, 3D views of the facility with live data from PLCs

- Source code is available. Contact us.

- Technology transfer services

- Additional training on the products & their behind-the-scenes plumbing details

- Leasing or lease/purchase option of whole or part of system.

Supported Operating Systems

Desktop PCs – Current MS Windows or earlier (32 & 64 bit); MS Windows Server (any version) Mobile Hardware – Use commodity iPads or Androids or Surface units for scanning, HMI or user interface, throughout the enterprise. Native mobile apps not just a virtual desktop. Use wireless ISA100, wirelessHART, Wi-fi, IR, Bluetooth, BLE, satellite, cell network or broadband of client’s choice.

Features/Benefits

- ERP/MES capability built-in or may interface with external products like SAP, Oracle, Dynamics etc.

- CMMS capability built-in or may interface with external 3rd party packages like SAP, InFor, Maximo

- Interface to any HMI/SCADA or PLC

- Test or debug simulation support (with source version control)

- Decision support, AI (Artificial Intelligence), Big-data, Iiot (Industrial Internet of Things)

- MS Azure Streaming Analytics, Google Analytics, AWS

- Any kind of presentation Dash-boards with KPI

- Digital Twins from Azure, AWS & some other DTs interface with real-time data in/out to control systems.

- Video Analytics via almost any brand of cameras

- 3D models like AutoCAD Revit; Inventor, Solidworks interface with control systems

- Integrated intelligent documents, drawings, c/e diagrams

- Support various smart glasses, Google NEST, Amazon echo, MS Cortana etc. use Blockchain for solid data traceability & tracking

- Integrate Drone technology for various apps.

- Maintenance CMMS, user, SNMP, documentation, asset management for IT & field sensors/instruments

- Operator comments of various types, with history

- Alarm management & notifications by various means

- Extensive Incident, Events management

- iBeacons, Eddystone, Zigbee, Lora, RFID, NFC, UWB support & localization

- Multi-lingual via Localization. Auto language switching.

- Standard and very complex custom reports via MS SQL reporting services or Report designers.

- scripting via MS Visual Studio, typically not with MS Office (e.g. VBA or VBScript) tools

- Redundant or clustered servers, multiple communication paths amongst resources.

- Automatic vital, critical data backup at cloud or multiple locations

- Archive the history data time limited only by storage space

- Control system hardware vendor-neutral. E.g. Rockwell/AB, GE-IP, Siemens, Schnieder, etc.

- Use Ladder, Structured Text, Function Blocks, IEC-61131, 61499 etc.

- Industry 4.0 & IIoT support using MQTT various flavors.

- Versions may be supplied in current MS Visual Studio to MS VB6 & MS SQL Server (any version).

- Can also work with HMI/SCADA systems like Rockwell, Schnieder, Siemens, ABB, Emerson, Honeywell etc. using any Fieldbus like ModbusTCP, ASI-bus, Profibus, Devicenet, Controlnet, Canbus, Ethercat, EthernetIP, etc. in any combination.

PCI carries full insurance for General & professional liability, etc. & comply with ISNetworld, Ariba, Avetta, SAM (Cage code) etc. All of PCI field personnel carry TWIC cards with H2S and Land Safety Training & have completed the IDAC HSE Rig pass course which includes SafeGulf and SafeLand USA.