Parijat FIRE & GAS Detection & Reporting NGSH-0705

Parijat Fire & Gas Detection & Suppression system operates as an intelligent GUI front-end to a variety of existing Fire & Gas detectors, Video cameras from various vendors & can be easily adapted to other vendor’s products that provide a communications port. It also can control the fire suppression devices by directing them to the precise area where the detection to achieve maximum effectiveness. It allows you to configure F&G devices as an overlay on top of any user created graphical images that may be a plot plans etc. The application software functions as an HMI for any NFPA (National Fire Protection Association) compliant F&G Detection and Alarm System. Drill-down details, diagnostics, documentations are available. Other general features are provided below:·

- Supports edge devices from several F&G vendors, IP Video, thermal Cameras, brand/model PLCs & fire suppression devices.

- Supports unlimited quantity of devices on up to 255 comports, unlimited IP addresses for TCP/IP.

- Allows integration as remote I/O to various PLCs, & annunciation, notification devices

- Allows creating unlimited user displays with background graphics files of type: jpeg, wmf, pic, bmp, etc. The background display may be dynamically changed.

- Supports live video if available with live measurement data.

- Show time progression map of how an event progressed.

- Store event related historical data & perform analytics.

- May replace a PLC, if desired.

- Allows usage of artificial intelligence, Digital Twins, Machine Learning or rules for reporting & reaction to events.

- Allows interactive interface to other systems via variety of means – Modbus, any industrial protocol, MS SQL Server database, MS .NET, OPC, ODBC, etc.

- Continuously monitors all areas for abnormal conditions. In the event of a hazardous situation being detected, the system shall initiate notifications.

- Complete maintenance history & device user documentation is also supported.

- International language support

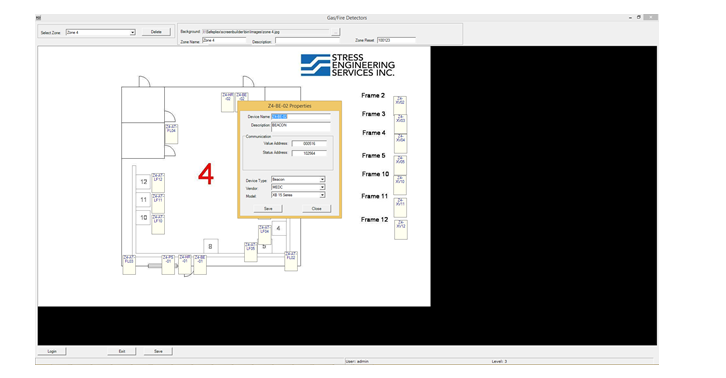

The design process is highly user-configurable, based on a “zone” concept. A “zone” is a defined F&G detection area consisting of a designated section of a facility; such as a plant, a process area, or a process unit. Each “zone” contains detectors, alarm devices, suppression devices etc. Each “zone” has a unique display showing all of its F&G related devices. The application consists of three major components that perform:

Configuration

- Define the number of zones in the system.

- Define the number, type and location of devices within each zone.

- Define the related operating parameters for each device as required.

- Define the Warning and Alarm values for each detector.

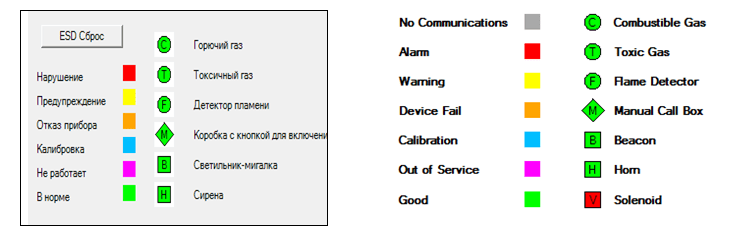

- Define the color code associated with each operating state.

- Provide a user selectable default zone display.

- Provide a means to import “Wallpaper” for each zone display.

- Provide a means to import product information for each device used in a zone. This data will be stored in a device library for use in other zones.

- Define Tag Names for use with PLC or other smart devices, if used.

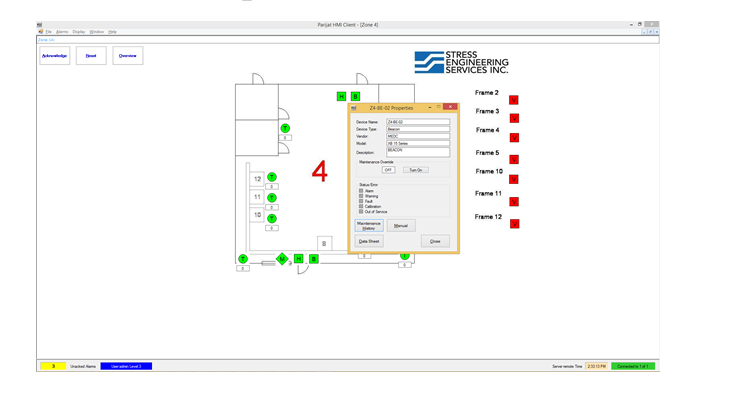

Run time

- Access the Overview Display.

- Access the Zone Displays.

- Access the Device Displays in each zone.

- Recognize and respond to Alarms and Warnings.

- Acknowledge Alarms and Warnings.

- Reset Alarms and Warnings.

- Activate Out of Service status for a device.

- Access the SOE Display.

- Access the Device Information Displays.

- Navigate between the above Displays.

- Determine the Health of the PLC, if used.

- HMI with Support in international languages.

Communication Driver Helps

- Transfer non-safety & safety-related data from any PLC or any smart devices to the application

- Transfer data to a Host System using any of over 100 host-supported protocols.

- Communicate with other smart devices for annunciation, notifications, or suppression.