Parijat Aluminum Extrusion SCADA NGSH-0701

The goal for extrusion operations is to produce the highest quality product at the lowest possible cost. Securing this efficiently requires a change in paradigm from operators pushing buttons and manually collecting data – to presses running in complete automatic, performance and production data being collected and transferred to the business, ERP system, while the equipment operators function as technicians concentrating on improving quality and productivity. The MIS, ERP system may be an existing 3rd party system like SAP, Oracle Financials, M2M, InFor, MS Dynamics, Epics etc. or it may be the integrated business systems option of the Parijat system.

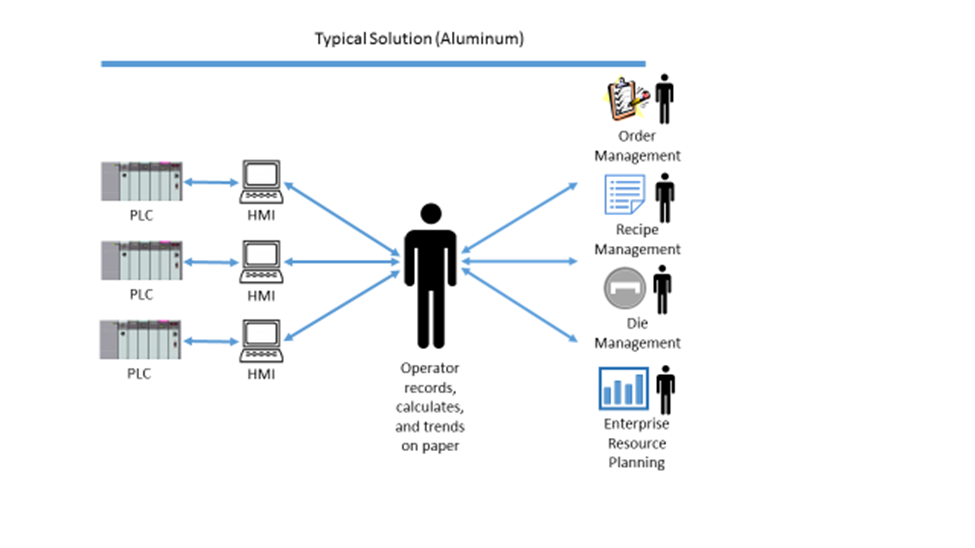

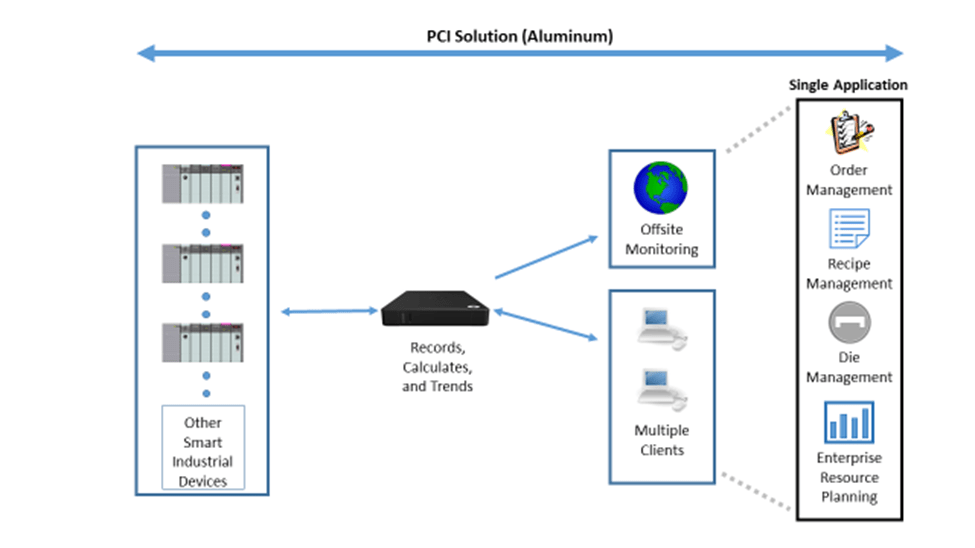

A Typical aluminum extrusion system solution consists of various software silos or islands from different vendors software products with multiple copies of data, also requiring a lot of manual data entry activities that are prone to human errors.

PCI solution combines all of these activities into a single software application with a single copy of data. This eliminates any data integrity complications & vulnerability to human data entry errors.

Automation

To get to this level, the press system – beginning with the billet / log heating and cutting system; billet loading system; press cycle, auto Die change; lead out table / hot saw / puller; profile handling transfer / stretching system; Cold / finish saw infeed, cutting, queuing, and offloading systems must be balanced; quenching air / water; PLC’s capable of communicating between themselves, running in automatic closed loop control mode and the PLC’s making process adjustments based on equipment settings, positions and computer algorithms all with minimal operator intervention. Examples of this type of automation are:

1. Automatic billet call settings based on press ram speed, billet length and dead cycle time.

2. Die Copy actual weight per unit length calculation based on puller positioning and billet size.

3. Automatic adjustment of billet length to maximize recovery, minimize press time.

4. Billet length calculations based on last recorded weigh per unit length of die copy.

5. Smoother & faster press cycle & smaller dead cycle time – even less than the press vendor spec.

6. Safety interlocks –

· Puller safety light curtains

· Hot saw protection

· Press safety alarms / stops – ram obstruction, billet misalignment, butt fall detection, short tool stack,

7. Auto generated shift reports & statistics – quantity of billets run, gross weight extruded, number of die changes, contact time.

8. Automatic burp pressure settings to minimize blisters, burp cycle.

9. Hot saw positioning in conjunction with billet length calculation to maximize recovery.

10. Automatic position / release of extrudate via recipe verses operator, or time controlled

11. Ram speed adjustments based on billet & exit temperature (Thermal camera/IR Pyro)

12. Finish saw automation, unattended operation after the stretcher trim is cut off so the saw operator can assist in racking metal.

Tracking & Traceability

Use advanced video analytics, Blockchain & IIOT (Industrial Internet of Things), Industry 4.0 to track & trace the materials used from entry of logs/billets to the finished products at plant exits.

Communications - data collection

Up till now data collection and analysis was quite arduous – many times data is not thoroughly collected or analyzed to determine what is preventing current system from running optimally – getting to root cause is the key. Even the oldest presses have the potential to run in full automatic or as a bare minimum semi-automatic. Parijat SCADA data collection system will provide with real time press performance and identify roadblocks to excellence. Parijat integrated single system will provide the cost savings models by modifying or correcting the issues which are keeping the press from being very profitable.

Once the press system is functioning at full potential, optimum recipes (press parameters) can be generated beginning with the highest volume shapes. These recipes get automatically pushed directly into PLC’s, once again reducing operator keystrokes and potential for human error. Infinite quantity & extensive recipe management system helps with the process optimization also. Parijat PLC programs & the PC software harness the full power of both sides coupled with the domain knowledge of Aluminum extrusion. This is done by focusing on total end to end Systems Integration:

- Develop drivers and software to cohesively integrate existing press PLC’s with existing business systems (ERP, MRP) or also perform those functions if an ERP system does not pre-exist as an integrated system.

- An extensive die management system to provide the tools to effectively analyze the performance of the presses down to the profile level, including automatic Die change over, if physical mechanisms exist.

- Presales quoting system – provide a quoting model which provide the production estimates and the optimum number of holes in a die. In a multi press operation this can be provided by multiple cost / profitability estimates based on different presses.

- Scheduling – provide easily manipulated Press Schedule – using existing ERP, MRP system. Including optimizing billet length, hot saw position, multi drags, multi push based on actual weight per unit length of theprofile.

- Collect – Labor, Burden, number of billets, length of billets, alloy, alloy lot number, actual weight per unit length of extrusion and run success based on PLC data communications without the need for the operator to input this data manually.

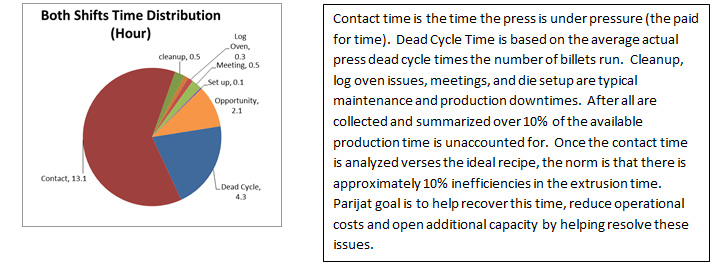

- Collection of “real downtime” or lost time – The following diagram shows time distribution of a typical extrusion 24-hour work day.

- Use of smart industrial buses like Ethernet, Controlnet, Devicenet, Profinet, IOLink etc.to significantly reduce wiring.

Parijat can help optimize the control systems and processes.

There are a number of other services Parijat offers, beyond trouble shooting, optimization and integration.

Training

Parijat team is fully capable of training client’s maintenance personnel on multiple PLC platforms – Rockwell, Siemens, GE, Schnieder, Mitsubishi, Honeywell, to name a few.

PLC Upgrades

if current press control system is running outdated PLC’s, Parijat can help upgrade it to the latest software and hardware available & harness their power to the fullest.

EMMT – Extrusion Maintenance Management Tool

this is an instant interactive, intuitive Visual fault diagnosis & trouble shooting tool for the maintenance team to trouble shoot equipment, without the PLC technician having to pull out the laptop and analyze the ladder logic. Parijat provides plant team members a virtual road map for trouble shooting which will significantly reduce system downtime by minimizing the trouble shooting of the equipment – EMMT points in the right direction.

Add on Options

1. Interfaces between ERP (e. g. SAP) such as Master Data Interface Order Interface, Die Interfaces and Batch Interface.

2. Digital extrusion process application Operator Screens- DWOs clubbing, delayed entry, quality code mapping, Basket Number mapping etc. Digital extrusion process application Operator Dashboards – Such as Batch Progress Dashboard, Critical Process Monitoring Dashboard Die Monitoring Dashboard.

3. Digital extrusion process application Operations Management Dashboard – Process and Condition Diagnostics, Billet Wise Comparative Analysis and Insights Correlation Analysis dashboard, Multivariate Analysis dashboard, Energy Consumption dashboard.

4. Digital extrusion process application KPI console – Asset Performance KPIs Business Performance KPIs Billet Reports KPI vs. golden Batch.

5. Digital extrusion process application isothermal control module- Auto learn functions, Fully Automatic Mode, Dynamic Calculation and control of Ram speed, Control of Isothermal temperature set-point, User-controlled regulation parameters including PID gain, & amp; Extrusion Ratio Control, Optimization start & amp; stop control.

6. Digital extrusion process application downtime system module – allows all downtime events and parameters collected from the extrusion operation and stored in a SQL database, provides programming of the event description, each event separated by ‘Operational’, ‘Technical’ and ‘Planned Stop’ – color coded, Event names in multiple languages selected by operator logon, Reporting through Dashboard and Downtime Reporting Module.

7. Digital extrusion process application recipe system module – allows individual programming and storage of all extrusion parameters for each dies & amp; dies copy which provides, Parameter storage for each Die copy / Master, Manual input of recipe creation parameters such as alloy type, alloy quality, die type etc., Exit camera set-up parameters, Offline editing, Supports auto exist pyrometer alignment, Recipe locking & amp; reporting of Operator ‘change’ events.

8. Digital extrusion process application furnace control module – allows control of press furnace and provides, designed to control furnace temperatures based on recipe settings, Integrates with Furnace PLC such that Locked recipe control is maintained, manages ‘First Billet’ temperatures based on Recipe settings, data-logs zone temperatures on furnaces with up to 12 zones.

9. Digital extrusion process application quench control module – allows Quench rates to be measured based on Exit Pyrometer to Quench 1 or Quench 2 Pyrometers which provide Real-time reading of quench rate allowing the operator to adjust quench settings, color coding to show quench when quench temperature is outside desired window graphical reporting per billet through the platform, Data logging of all quench measurements for later analysis or playback provides a graphical display of quench temperature and quench rate.

10. Digital extrusion process application exit camera alignment Interface module – assuming customer-supplied actuator is in place with manual controls and feedback of position to PLC which allows exit camera to be aligned to recipe stored position on die change with instruction to the press operator which can be used with manual movement of the camera but not recommended with locked recipes, zero position calibration Scan for best measurement Position (available currently on Land pyrometer with actuator auto alignment to profile ‘hot-spot’, fixed position alignment, zero position calibration.

11. Digital extrusion process application billet camera alarm interface module – provides alarm and data logging of Billet temperature at the point of billet load. Press ‘stop’ capability if the measured temperature is outside user-programmed values.

12. Digital extrusion process application for ageing station – Traceability of each production order or batch with a display of each order contained in the baskets for easy access to order status at any time, to analyze throughput of good pieces and scrapped pieces (trend), Visualization and data saving (Report) of Bars, Passed Time, remaining time, Set point Temp, Actual Temp, trend, label print dashboard options.

13. Digital extrusion process application DIE SHOP Station – the die oven visualization page, managing of information referred to the die life as well as the die shop, At every production, the system saves and automatically updates kg/m of produced profile for each die as well, Status Tracking, Reports (Correction planning, Dies sent to Nitruration, Dies waiting for Nitruration Die List for Customer, Repaired Die List, Dies Out of Service List) Standard reports available: Correction Planning, Dies Sent to Nitriding, Wait for to Nitriding Dies, Die List for Customer, Repaired Die List, Dies Out of Service List.

14. Digital extrusion process application order management station (Daily order schedule /Production planning) Single order visualization: commercial data, technical data coming from the external data source. ERP, Order Planning, Scheduled orders summary with press and stacker situation, page of technological parameters insertion, page for orders to be completed, page for Order Status (Planned, In extrusion, at Press, at Stacker, at Packing, Completed), Automatic lots grouping, Reports (Billet Per Billet, Die, Down time, die change, Current), Die life management, Archive management, Die draws visualization. Draws will be supplied by customer in PDF format (if available), Database connected, Down Time, Die change reason set, Lock Recipe, Press Capacity in time, Label Print – if required, Billet and Scrap Length Optimization, to avoid the extrusion of partial section, Treatment type, Interface with ERP and SQL database for 1 extrusion line, Development of database interface between our Production Data Management and your existing ERP. The interface automatically imports all data about order production (without the operator). By this way, each press has daily, weekly order production list as planned in ERP.

Various OEM equipment that may be supported:

Presses: UBE, SMS Meers, Mei-Ruey, Tecalex, Presezzi, Gia Clesim, Siddharth heavy ind, Guangzhou DT, Danieli, Kautec,

Shears: Belco, Granco Clark, Omav, Tecalex, Cometal, Kautec, Presezzi, SMS Meers, GIA Cleceim, Turla

Furnaces: Belco, Granco Clark, Omav, Tecalex, Furnace Engineering Pty Ltd, Cometal, Kautec, Presezzi, GIA Cleciem, Turla

Pullers: Granco Clark, REISCH Maschinenbau GmbH, Cometal, OMAV, Kautec, Presezzi, Belco, Turla

Straighteners: SMS Meers, Butech Bliss, Granco lark,

Other Ancillaries: Tecalex, Omav

To begin the process, Parijat requires as much detailed information on press configurations as follows:

Click on download to get PDF