Introduction

Automation has become an integral part of modern industries, revolutionizing the way businesses operate and boosting efficiency across various sectors. At the core of automation systems lie Supervisory Control and Data Acquisition (SCADA) and Human Machine Interface (HMI) technologies. SCADA/HMI systems empower organizations to monitor, control, and manage complex industrial processes in real-time. In this comprehensive guide, we will explore the role of SCADA/HMI in industrial control systems, highlighting their importance in driving operational efficiency and achieving seamless control.

Understanding SCADA/HMI in Industrial Control Systems

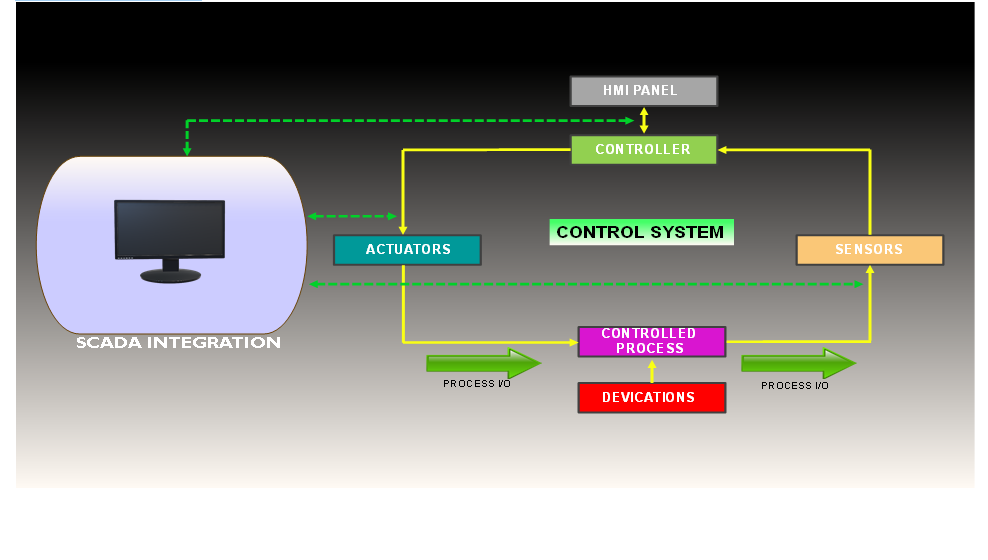

SCADA/HMI systems are the backbone of industrial control systems, enabling centralized control, monitoring, and data acquisition. SCADA acts as the central hub that collects and analyses data from sensors, equipment, and devices throughout the industrial process. On the other hand, HMI provides a user-friendly interface for operators to interact with the SCADA system, facilitating control and decision-making.

Enhancing Operational Efficiency

The integration of SCADA/HMI systems in industrial control systems brings numerous benefits. Firstly, these systems provide real-time data on key performance indicators, enabling operators to monitor processes and make informed decisions promptly. With advanced visualization tools, operators can easily interpret complex data, identify trends, and implement necessary adjustments to optimize system performance.

SCADA/HMI systems also enable efficient control by providing a comprehensive overview of industrial processes. Operators can monitor and adjust various parameters, such as temperature, pressure, and flow rates, in real-time. This capability not only improves the precision and accuracy of control but also reduces the risk of human error.

Enhancing Operational Efficiency

One of the key advantages of SCADA/HMI systems is their ability to enable remote monitoring and control. With the increasing complexity and geographical spread of industrial operations, this feature proves invaluable. Operators can access the SCADA/HMI interface from anywhere, allowing them to monitor and control processes remotely. This capability improves operational flexibility, reduces response times, and ensures swift actions in case of emergencies or abnormal situations.

Data Acquisition and Analysis

SCADA/HMI systems play a vital role in data acquisition and analysis, facilitating informed decision-making and process optimization. By collecting data from various sensors and devices, these systems provide valuable insights into process variables, equipment performance, and energy consumption. With advanced analytics capabilities, operators can identify patterns, detect anomalies, and predict potential issues, enabling proactive maintenance and preventing costly breakdowns.

Conclusion

SCADA/HMI systems are crucial in industrial control systems, providing centralized control, real-time monitoring, and data acquisition. They enhance operational efficiency, enable remote monitoring, and control, and empower businesses to make informed decisions for process optimization. Parijat Controlware Inc. offers comprehensive services tailored to maintain and optimize SCADA/HMI systems. With our expertise in maintenance, cybersecurity, and system optimization, we ensure seamless control, enhanced efficiency, and minimized risks. Partnering with us allows businesses to focus on core operations, knowing their control systems are in capable hands. Together, we drive success in the era of industrial automation.