Introduction

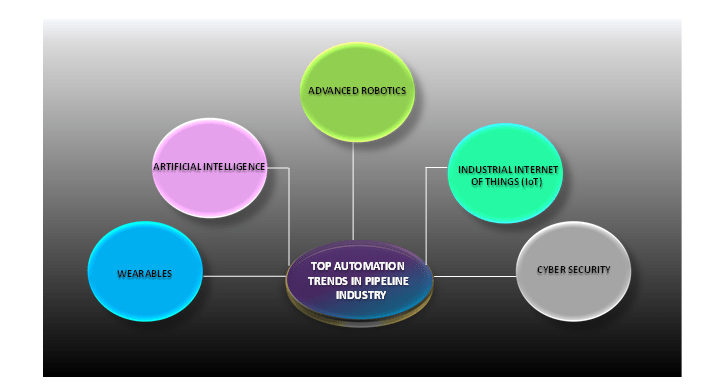

In a rapidly evolving world, the pipelines industry is embracing the potential of industrial automation solutions to revolutionize its operations. With the integration of cutting-edge technologies, pipelines are becoming smarter, safer, and more efficient. This article delves into the remarkable ways in which automation is reshaping the pipelines industry. From enhancing safety and reliability to optimizing asset management and promoting regulatory compliance, we will explore the multitude of benefits brought by industrial automation. Additionally, we will highlight the exceptional services offered by Parijat Controlware, Inc., a visionary provider of tailored industrial automation solutions in the pipelines sector.

Enhanced Safety Measures: Safeguarding Pipelines and the Environment

In an industry where safety is paramount, industrial automation solutions have emerged as invaluable tools. Through the utilization of advanced systems, such as Supervisory Control and Data Acquisition (SCADA), operators gain real-time insights into pipeline operations. Automated leak detection mechanisms ensure early detection and swift responses to any anomalies, safeguarding pipelines and minimizing environmental risks. With safety as the top priority, the pipelines industry has witnessed a significant reduction in accidents and a heightened level of confidence in its operations.

Seamless Remote Monitoring and Control: Empowering Efficiency

The advent of industrial automation solutions has ushered in a new era of remote monitoring and control. Leveraging the Internet of Things (IoT), operators can remotely gather and analyze data on critical pipeline parameters. Real-time monitoring of pressure levels, temperature, and flow rates enables operators to make informed decisions, optimize operations, and address issues promptly. This remote capability enhances operational efficiency, minimizes the need for manual inspections, and optimizes resource utilization.

Moreover, automation enables the implementation of advanced algorithms that can detect abnormal patterns in pipeline data. By leveraging machine learning and AI, these algorithms can predict and alert operators of potential risks or system failures. The ability to detect and respond to abnormalities in real-time ensures that corrective actions can be taken swiftly, preventing potential accidents or disruptions in the pipeline network.

Predictive Maintenance and Optimal Asset Management: Ensuring Reliability

Predictive maintenance, made possible through industrial automation solutions, has transformed asset management in the pipelines industry. By harnessing the power of data analytics, machine learning, and AI algorithms, operators can proactively monitor the health of essential components like valves, pumps, and compressors. Predictive maintenance algorithms analyze sensor data and historical patterns to predict equipment failures, facilitating timely maintenance interventions and extending the lifespan of assets. This proactive approach reduces downtime, optimizes maintenance schedules, and ensures the reliability of pipeline infrastructure.

In addition to predictive maintenance, automation technologies also enable condition monitoring of assets in real-time. Sensors installed on critical equipment continuously collect data on factors such as temperature, vibration, and performance metrics. This data is then analysed using advanced algorithms to identify potential issues or deviations from normal operating conditions. By detecting early warning signs of equipment degradation or malfunction, operators can schedule maintenance activities proactively, preventing unexpected breakdowns and minimizing disruptions to pipeline operations.

Boosting Efficiency and Driving Cost Savings: The Power of Automation

Industrial automation solutions have become key drivers of efficiency and cost savings in the pipelines industry. Automation streamlines processes, eliminates manual tasks, and minimizes human errors. Intelligent algorithms optimize pipeline flow rates, enhancing resource utilization and reducing energy consumption. Additionally, automated systems optimize transportation logistics, improving delivery schedules, and minimizing downtime. These efficiency gains lead to substantial cost savings for pipeline operators, ensuring their competitiveness in the market.

Automation technologies also enable the integration of data-driven decision-making processes in pipeline operations. Advanced analytics and machine learning algorithms can analyze vast amounts of data collected from sensors, historical records, and external sources to optimize various aspects of pipeline management. This includes optimizing routing and scheduling of shipments, predicting demand fluctuations, and identifying opportunities for operational improvements. By harnessing the power of data, automation allows operators to make informed decisions that maximize efficiency and profitability.

Adhering to Regulations with Ease: Streamlining Compliance

Regulatory compliance is a crucial aspect of the pipelines industry, and automation solutions streamline this intricate process. Automated systems accurately capture and store operational data, ensuring compliance with regulatory requirements and facilitating efficient reporting. Automation also simplifies documentation processes, relieving pipeline operators of administrative burdens. With streamlined compliance processes, operators can focus on core operations while maintaining the highest standards of regulatory adherence.

Parijat Controlware, Inc. is a pioneering force in delivering customized industrial automation solutions to the pipelines industry. With expertise in cutting-edge technologies like SCADA systems, IoT integration, and predictive analytics, Parijat Controlware empowers pipeline operators to optimize performance, enhance safety, and drive operational excellence. By collaborating closely with clients, Parijat Controlware tailors solutions to their unique requirements, ensuring seamless integration and unlocking the full potential of automation.

Parijat Controlware’s services encompass comprehensive system design, implementation, and ongoing support. Their team of highly skilled engineers works closely with pipeline operators to understand their specific needs and challenges, leveraging the latest automation technologies to deliver innovative solutions. Parijat Controlware’s expertise extends to areas such as network infrastructure design, cybersecurity, data analytics, and system integration

Conclusion

Industrial automation has propelled the pipelines industry into a new era of efficiency, safety, and regulatory compliance. Through enhanced safety measures, remote monitoring, predictive maintenance, and streamlined operations, pipelines are equipped to meet the challenges of a rapidly changing world. Parijat Controlware’s unwavering commitment to providing exceptional automation services positions them as a trusted partner for pipeline operators seeking to harness the transformative power of automation. Together, the pipelines industry and Parijat Controlware are paving the way towards a future where automation drives unparalleled performance and success.

With a focus on safety, efficiency, reliability, and compliance, the pipelines industry is embracing industrial automation solutions as indispensable tools in its operations. As the industry continues to evolve, the adoption of automation technologies will play a crucial role in driving its growth and sustainability. By partnering with Parijat Controlware, pipeline operators can navigate this transformative journey with confidence, leveraging their expertise and tailored automation solutions to achieve new heights of excellence.