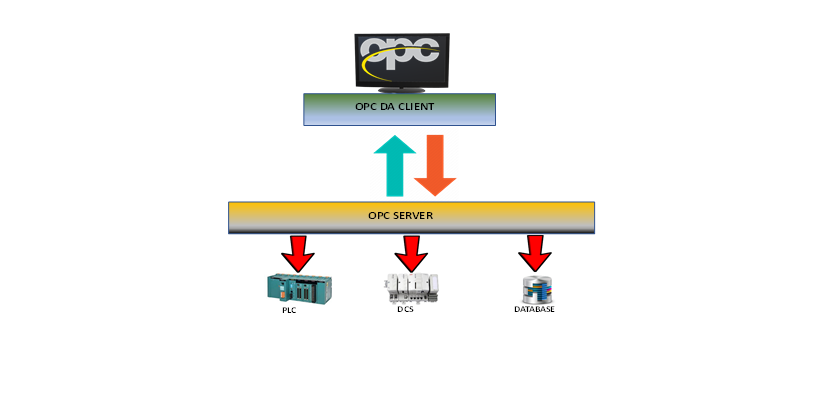

OPC DA (OLE for Process Control Data Access) is a communication standard used for transferring real-time data between industrial automation systems and other software applications. It provides a platform-independent method of accessing process control data and allows data to be exchanged between multiple systems, regardless of the underlying technology. OPC DA is widely used in manufacturing and process control industries, as well as in building automation, utilities, and transportation. The standard allows for real-time data collection and provides access to important information such as process variables, alarms, and performance data. This enables organizations to monitor and control their processes more effectively, improving efficiency, reliability, and safety. With its ability to provide seamless data transfer and integration, OPC DA is an essential component of modern industrial automation systems.

Parijat Controlware. Inc (PCI) offered OPC DA Solutions

PCI is a leading provider of smart solutions for OPC DA. OPC DA is a widely used industrial automation protocol that enables real-time data transfer between control systems, field devices, and higher-level enterprise systems.

PCI OPC DA solutions are designed to meet the needs of organizations that require reliable and efficient data transfer for industrial automation. These solutions are built with the latest technologies and are designed to be easy to use and manage, while still providing the highest levels of performance and security.

PCI OPC DA solutions can provide real-time data transfer, even in the most demanding environments. These solutions are designed to handle large amounts of data and can operate in harsh industrial environments, including high temperatures, electromagnetic interference, and high humidity.

In addition to their performance, PCI OPC DA solutions are also designed to be flexible and scalable. Organizations can choose from a range of OPC DA solutions to meet their specific needs, including standalone devices and integrated solutions that can be integrated into existing network infrastructure. Another advantage of PCI OPC DA solutions are their ability to provide advanced security features. These solutions are designed to protect against unauthorized access, tampering, and data breaches, ensuring that sensitive data is kept secure.

Key Features of the PCI offered OPC DA solutions

Here are some key features of the PCI offered OPC DA Solutions mentioned below.

1. Real-time Data Access: PCI OPC DA solutions provide real-time access to data from PLCs, DCSs, and other industrial control systems.

2. Wide Range of Device Support: The solutions support a wide range of devices and communication protocols, making it easier to integrate existing systems into the overall OPC infrastructure.

3. Scalable Architecture: PCI OPC DA solutions can be scaled to accommodate the needs of large and complex industrial operations.

4. High Availability: The solutions are designed with high availability in mind, ensuring that data is available even if one or more devices fail.

5.Secure Data Transfer: PCI OPC DA solutions use secure communication channels to transfer data between devices, reducing the risk of data tampering or unauthorized access.

6. Easy to Use: The solutions are designed with user-friendly interfaces that make it easy to configure, monitor, and manage OPC data and devices.

7. High-Performance Data Access: PCI OPC DA solutions offer fast and efficient data access, reducing the time it takes to access and process data.

8. Flexible Deployment Options: PCI OPC DA solutions can be deployed on-premises, in the cloud, or as a hybrid solution, providing customers with flexible deployment options.

9. Reliable Data Quality: PCI OPC DA solutions ensure that data is accurate, complete, and free of errors, making it easier to make informed decisions based on the data.

Use Cases

Conclusion

PCI is a leading provider of smart solutions for OPC DA. Their solutions are designed to meet the needs of organizations that require reliable and efficient data transfer for industrial automation and are built with the latest technologies to provide the highest levels of performance and security. Whether you need a standalone device or an integrated solution, PCI has the expertise and experience to provide an OPC DA solution that meets your needs and helps keep your sensitive data secure.