Introduction

The offshore industry is witnessing a profound transformation through the integration of advanced automation solutions. Automation has emerged as a game-changer, revolutionizing offshore operations by enhancing efficiency, productivity, and safety. This article explores the profound impact of automation services on offshore industries, delving into the multitude of benefits they offer. Whether you are a professional in the offshore industry, a decision-maker, or simply interested in the future of offshore operations, this article provides valuable insights into the transformative power of automation.

What does the Parijat HMI/SCADA do for my HMI/SCADA?

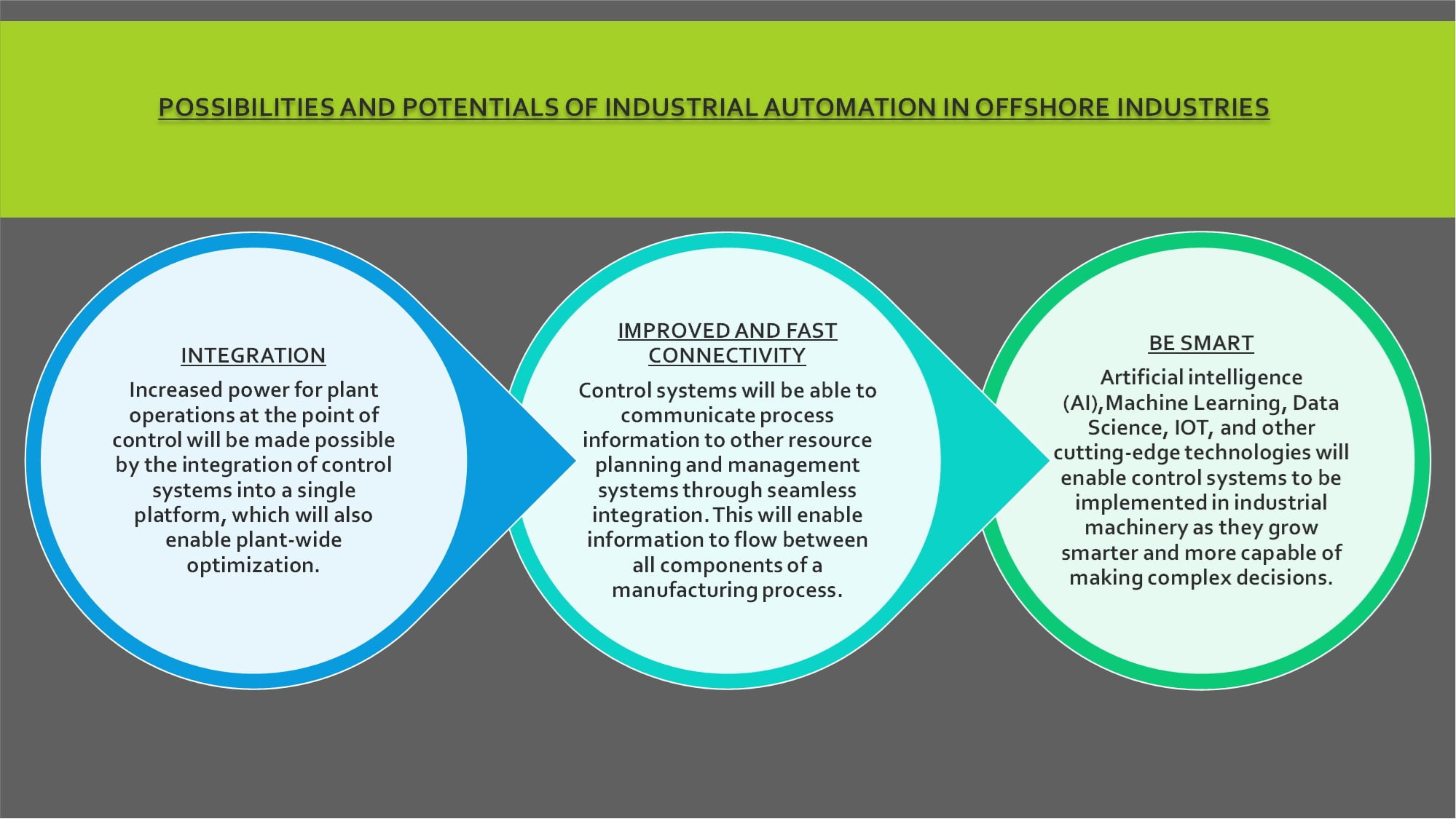

- Streamlining Offshore Operations with Control Systems: Automation services leverage cutting-edge control systems to streamline offshore operations. These systems encompass a range of technologies, including distributed control systems (DCS), programmable logic controllers (PLC), and supervisory control and data acquisition (SCADA). By seamlessly integrating these technologies, automation optimizes process control, enhances operational efficiency, and enables real-time monitoring of critical parameters.

Efficient process control is crucial in offshore operations, where numerous complex systems work together. The integration of control systems allows for centralized monitoring and control, enabling operators to make informed decisions based on real-time data. With improved process control, offshore industries can enhance safety, optimize resource allocation, and reduce operational costs.

- Leveraging Robotics for Enhanced Efficiency and Safety: The integration of robotics in offshore industries has revolutionized the way tasks are performed. Automation services leverage robotics for various applications, such as inspection, maintenance, and logistics. Robotic systems equipped with advanced sensors and manipulators can operate in hazardous environments, reducing human exposure to risks and improving overall safety. By automating repetitive and physically demanding tasks, robotics enhances operational efficiency and productivity.

Robotic systems are particularly useful in offshore industries where manual labour in harsh environments can be challenging and risky. Autonomous underwater vehicles (AUVs) and remotely operated vehicles (ROVs) equipped with cameras and sensors enable efficient inspection and maintenance of underwater structures and pipelines. These robotic systems can navigate complex underwater environments, collect data, and perform tasks with precision, ensuring safety and minimizing human intervention.

- Harnessing the Power of Artificial Intelligence (AI) in Offshore Operations: Artificial Intelligence (AI) plays a pivotal role in optimizing offshore operations. Automation services utilize AI algorithms to analyse vast amounts of data collected from sensors, cameras, and other sources. This enables predictive maintenance, anomaly detection, and intelligent decision-making. By leveraging AI, offshore industries can identify potential issues before they escalate, thereby minimizing downtime and maximizing asset utilization.

AI-powered systems can detect patterns, trends, and anomalies in large datasets, providing valuable insights for offshore operators. Predictive maintenance algorithms analyse equipment performance data to identify signs of potential failures or maintenance needs. This proactive approach allows operators to schedule maintenance activities strategically, reducing unplanned downtime and optimizing the lifespan of critical assets.

- Real-time Monitoring and Remote Control for Offshore Assets: Automation services offer real-time monitoring and remote-control capabilities for offshore assets. Through the integration of IoT devices, sensors, and connectivity solutions, offshore operators can remotely monitor critical equipment, collect data, and make informed decisions in real-time. This enables prompt response to anomalies, reduces downtime, and improves overall operational efficiency.

Real-time monitoring systems provide continuous updates on the condition and performance of offshore assets. Operators can access this data remotely, allowing them to identify and address issues promptly. Remote control capabilities enable operators to adjust parameters, initiate maintenance actions, and troubleshoot problems without physical presence on-site. This significantly improves response times, minimizes downtime, and enhances the overall efficiency of offshore operations.

- Enhancing Safety and Risk Mitigation with Automation: Safety is of paramount importance in offshore industries, and automation services play a crucial role in mitigating risks. Advanced monitoring systems, coupled with data analytics and machine learning algorithms, enable early detection of potential hazards, such as equipment failures or leaks. Automation services empower operators to take preventive measures, ensure compliance with safety protocols, and respond effectively to emergencies, safeguarding personnel, and assets.

Integrated safety systems monitor various aspects of offshore operations, including equipment performance, environmental conditions, and personnel safety. Real-time data analysis and machine learning algorithms enable the detection of abnormal behaviour or conditions that may pose risks. Proactive alerts and automated response protocols ensure that potential hazards are addressed promptly, minimizing the likelihood of accidents, and ensuring a safe working environment.

- Environmental Sustainability in Offshore Operations: Automation services contribute to environmental sustainability in offshore industries. By optimizing energy consumption, minimizing emissions, and implementing efficient waste management systems, automation solutions help reduce the environmental impact of offshore operations. This not only aligns with regulatory requirements but also enhances the industry’s reputation as a responsible steward of marine ecosystems.

Energy optimization algorithms ensure that offshore facilities operate at peak efficiency, minimizing energy waste and reducing carbon emissions. Advanced monitoring systems detect leaks or spills, enabling quick responses to mitigate environmental damage. Furthermore, automated waste management systems optimize the handling, treatment, and disposal of waste materials, reducing the ecological footprint of offshore operations.

Conclusion

Automation services have brought about a transformative shift in offshore industries, driving increased efficiency, productivity, and safety. Through the integration of advanced control systems, robotics, AI, and real-time monitoring capabilities, offshore operations are optimized for enhanced performance and sustainability. Parijat Controlware, a leading provider of automation solutions, offers tailored services that cater to the unique needs of the offshore industry. With their cutting-edge technologies and expertise, Parijat Controlware empowers offshore businesses to navigate the digital era and achieve operational excellence. Together, we can embrace the power of automation and forge a future where offshore industries thrive in an efficient, sustainable, and safe manner.