Parijat HMI/SCADA MS Visual Basic.NET Open-source Development System

Microsoft® VB.NET™ , C#, Xamarin Configurable, scalable, maintainable

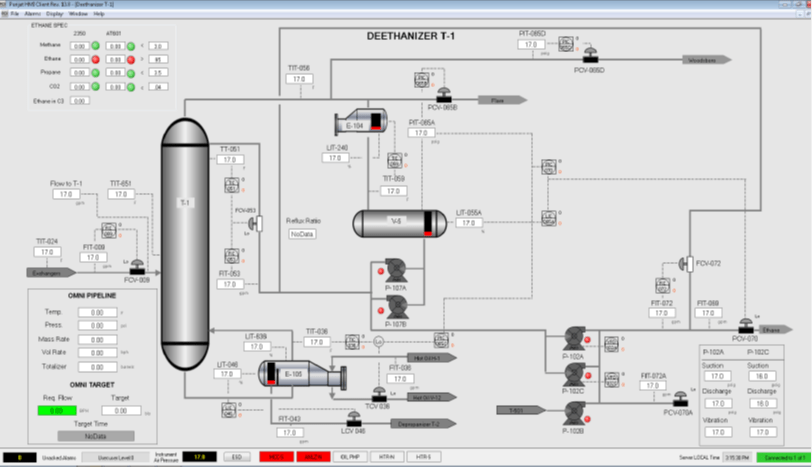

This product developed under Microsoft Visual Basic .NET (Currently using native 64-bit managed latest VB.NET & MS SQL) for Desktop Windows or internet web browser environment. It lets you rapidly build full-featured Human Machine Interface (HMI) or SCADA systems for any applications to PLCs, IEDs, DCS, Flow Computers, Chromatographs, and/or any system where data needs to be reported in a tabular/graphical format, or a GUI to database system. This development rivals proprietary non-Microsoft 3rd party products like Intouch/Archestra/Citect/Clearscada/Telvent/Oasis/Indusoft from Schnieder, iFix/Proficy/Cimplicity from GE-IP, PlantPax/Factorytalkview/RSView32/Panelview from Rockwell-AB, WinCC from Siemens, GenesisÔ from Iconics, Ignition from Inductive Automation etc. and provides the configurability, scalability, and maintainability so that individuals with minimum exposure to VB can quickly master and build HMI applications.

If you are using 3rd party (to Microsoft) proprietary HMI or SCADA products from companies other than Microsoft, and are having issues with the features, configurability as well as their licensing policies, costs, support delays and limitations then Parijat has an open-source solution for you.

What does the Parijat HMI/SCADA do for my HMI/SCADA?

Use MS VB.NET as the rich development editor, surpassing features of any 3rd party HMI/SCADA editors. Define the points/tags to read/write using a GUI & store the configuration in a pre-built open MS SQL server DB schema. Enter appropriate data for polling, trending, history, alarming, limits and scaling via MS SQL management studio or free Parijat Config utility.

Select as many of the pre-built PLC communication drivers as needed for your application.

Use VB.NET as the editor for building, animating or coding the HMI Display Forms for client. You just need to copy the sample Form from the template (examples provided). Drop your required VB controls on it, making the display suiting your application. Then, with the Parijat Control Wizard “link” a VB control (Label, Textbox, Picturebox, and other controls) to a reference address in the PLC data (word or bit). Via this control wizard the user may also specify different types of animation configurations for this VB control. The configuration is stored in the .Tag property of the control. You may also use other MS or 3rd party controls. The wizard requires non-Express edition of MS Visual Studio (VS). Most features given below are a direct derivative of MS Visual Studio.

The control Tag property may also be set independently via the VB editor to provide different display/form specific configurations without the wizard. The project also is supplied with some HMI specific controls, built by PCI.

The product generally consists of four components:

- A .NET service or desktop app running as a server, responsible for communication with field devices, alarms and historians

- A .NET client application for creating the user display forms, and animations of VB objects (Source Code provided).

- An MS SQL Server 2000 or later (CE, Express or above, LocalDB, Sql-lite) database structure, schema for data population, specific to your application of HMI/SCADA. A front-end editor utility is provided. Or use any other tools for MS SQL Server edits.

- A Parijat control wizard to help edit the .TAG property of animated controls.

Features & Benefits:

- It is a typical VB or C# standard executable project. No run-time royalties.

- Support for about 100 industrial communication protocols (more being continuously developed). Or read/write data from MS Excel, MS SQL server, OPC-UA, OPC-DA, RESTful API, XML, Jason, Google Sheets, ApacheAVRO, YAML, TOML etc. . For any other data formats, please contact PCI.

- Designed to make use of the fast throughput and exception based processing of VB.NET & C#

- Unlimited points or Tags, displays, clients.

- Powerful animation and various Windows graphical file support for symbols.

- Multi-lingual support via MS VS & Windows localization.

- Version control & multi-developer facility via MS VS Team Edition.

- Secure & compliance with DISA via MS Team servers etc.

- Easy multi-client distributed deployment/publishing of runtime updates via ClickOnce of MS VS.

- Does NOT limit you

from using any other capabilities of VS in any way. Use any 3rd party controls also. - Make any changes to points/tags without stopping the server.

- Client app can access data from multiple servers, allowing you to create a huge corporate system.

- Designed for field personnel, who are not VB programmers. For typical HMI screen modifications, no VB code needs to be written.

- Uses Microsoft SQL server for storing system configuration, near-term history & archive historian. Extend it to use this or any other database for any applications. Unlimited Storage space.

- Very powerful, advanced data analytics, KPI calculations.

- Runtime scripting via .NET compiler C# scripting API.

- Ideal for IoT applications due to support of push/pull, Post with RESTful etc.

- Extensive logging built-in for client, server & database editor.

- Any logic or sequential control, if desired, may be implemented via client and or server or MS SQL server.

- Easily create and manage simple/complex Reports using built in MS reporting tools.

- Built in support for Email, SMS Notifications with escalation. Send pre-built reports at preset intervals.

- Support for mobile devices via native & web apps.

- Configure HMI displays by setting properties of Microsoft provided or 3rd party controls, if chosen.

- Configurable scanning of foreign smart devices like PLCs, DCS. Flow meters and so forth.

- Can be an OPC server or OPC client. (When using OPC, the project becomes non-managed)

- No multi-sourcing, no need to have multiple applications from multiple non-Microsoft vendors.

- Integrate ALL the business system needs and the HMI into ONE single application.

- Very powerful alarming and trending capabilities (unlimited pens).

- Complicated Communication & screen update issues are resolved.

- Several pre-built symbols provided. You may create your own or buy third party symbols in standard BMP, JPG, JPEG, GIF etc. formats.

- Redundant server capability without expensive clustering hardware or licenses.

- Technology Transfer services is available from Parijat.

- Leverages Microsoft’s research in software development.

Special Applications:

- Electrical Substations & Distribution (Underground, aboveground)

- Oil & Gas Production

- Terminals

- Natural Gas Processing

- Ammonia

- Specialty Chemicals

- Fire & Gas

- Chemical Labs

- Marine ship management

- Aluminum Extrusion

- Water & waste water

- Distribution Centers

- Packaging lines

- OEM

- General Manufacturing

Please contact us for more details on the above.

Utility Applications:

- Protocol Conversion – use any driver(s)

on one side and any driver(s) on the other side. - Historian – Extremely powerful

- Restful Interface

- PLC to SQL, Restful

Minimum Requirements:

- Microsoft Visual Basic .NET Express, Community or better (for HMI editing only for non-Xamarin).

- Microsoft C# Express, community, or better (for HMI editing only, for Xamarin. Forms)

- Microsoft Windows XP, Vista, 7 (use older than VS 2010), 8.1 or newer. Any Windows server 2003 or newer. MS SQL Server CE, Express or above with 2000 or newer for database

- PC with RAM or CPU comfortable for Win Desktop OS of your choice. (Higher configurations apply for systems with > 500 points and historian needs)

- Use one or more Parijat .NET communication drivers.

Options:

- Source Code for the MS SQL Server Config utility.

- Source Code for the HMI Server .NET application.

- HMI Parijat Control wizard and/or its Source Code.

- HMI Display Builder (ParDesigner)

- Multi-client application update utility

- New driver or scanner applications