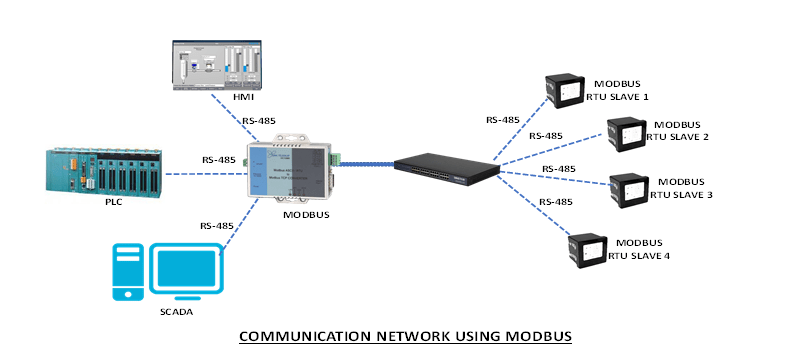

Modbus is a communication protocol used in industrial control systems and building automation. Modbus provides a simple and reliable way for different devices and systems to communicate with each other over a network. Modbus uses a master/slave architecture, where one device acts as the master and initiates communication, while other devices act as slaves and respond to the master’s requests. The protocol supports a wide range of functions, including reading and writing data from/to registers in devices, as well as reporting on device status and diagnostics.

Modbus is widely used in a variety of industries, including manufacturing, power generation, and building automation, due to its simplicity, reliability, and support for a range of devices and platforms. Today demand for IoT-enabled devices and systems has increased, and Modbus has been adapted to support Ethernet and TCP/IP communication, allowing it to be used in these new systems. This has expanded the reach of Modbus, making it a popular choice for industrial communication in the age of Industry 4.0.

Parijat Controlware. Inc (PCI) Modbus Protocol based Systems

PCI provides control systems and communication solutions for industrial and building automation. One of the key products offered by PCI is Modbus-based control systems, which use the popular Modbus communication protocol to provide reliable and flexible communication between different devices and systems.

Modbus is a widely used industrial communication protocol that provides a simple and reliable way for different devices to communicate with each other. The protocol supports a wide range of functions, including reading and writing data from/to registers in devices, as well as reporting on device status and diagnostics. By using Modbus, PCI control systems are able to integrate seamlessly with a wide range of other devices and systems, making them an ideal choice for industrial and building automation applications.

PCI Modbus-based control systems are flexible. The systems can be configured to meet the specific requirements of each application, providing a customized solution that is tailored to the needs of the customer. Whether the requirement is for a simple system that controls a single process, or a complex system that integrates multiple processes and devices, PCI control systems can meet the needs of the customer. PCI Modbus-based control systems are also highly reliable and robust, ensuring that they will continue to operate even in harsh industrial environments. This makes them an ideal choice for applications where downtime is not an option, such as power generation, manufacturing, and building automation.

PCI Offered Modbus Based Systems Key Features

Modbus is a widely used industrial communication protocol that provides several key features for industrial and building automation applications. Here are some of the key features of Modbus:

1. Simple and flexible communication: Modbus uses a master/slave architecture, where one device acts as the master and initiates communication, while other devices act as slaves and respond to the master’s requests. This simple and flexible communication architecture allows different devices and systems to communicate easily with each other.

2. Wide range of functions: Modbus supports a wide range of functions, including reading and writing data from/to registers in devices, as well as reporting on device status and diagnostics. This makes it an ideal choice for a variety of industrial and building automation applications.

3. Robustness: Modbus is designed to operate even in harsh industrial environments and can continue communication even in the presence of errors or other communication issues. This makes it a reliable choice for applications where downtime is not an option.

4. Support for multiple transport layers: Modbus can be used over a variety of transport layers, including serial and Ethernet communication. This makes it an ideal choice for a variety of industrial and building automation applications and allows it to be easily integrated into existing systems.

5. Wide availability of tools and libraries: Modbus is a well-documented protocol, and there are many libraries and tools available for integrating Modbus into control systems. This makes it an easy choice for developers and system integrators.

6. Interoperability: Modbus is a widely used protocol, and as a result, it is supported by many devices and systems from many different manufacturers. This makes it an ideal choice for applications where interoperability between different devices and systems is important.

These are some of the key features of Modbus that make it an ideal choice for industrial and building automation applications. By providing simple, flexible, and reliable communication, Modbus has become one of the most popular industrial communication protocols in use today.

Conclusion

PCI Modbus-based control systems provide a flexible, reliable, and robust solution for industrial and building automation applications. By using the widely used Modbus communication protocol, the systems are able to integrate seamlessly with other devices and systems, making them a popular choice for customers looking for a reliable and flexible control solution.