Introduction

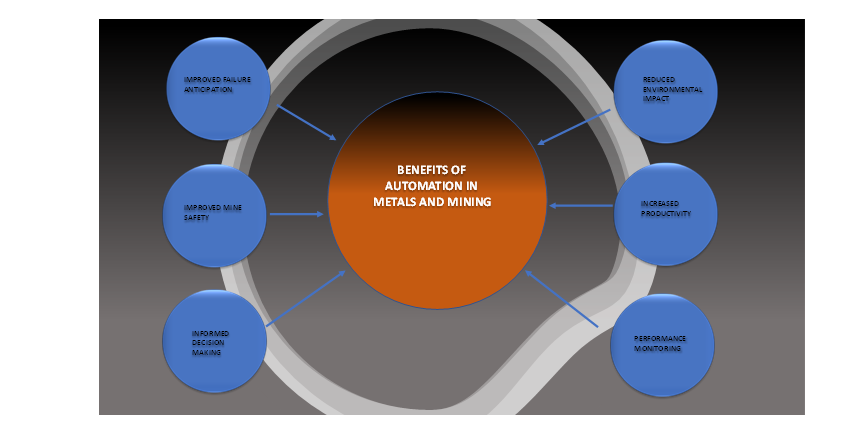

The metal and mining industry is undergoing a revolutionary transformation fuelled by the relentless advancement of automation solutions and cutting-edge technologies. From robotics and artificial intelligence to data analytics and Internet of Things (IoT), the industry is embracing these innovations to optimize operations, enhance safety, and drive unprecedented levels of productivity. This revolution is reshaping traditional mining practices, unlocking new possibilities, and paving the way for a future where efficiency, sustainability, and profitability coexist harmoniously. In this article, we will delve into the exciting realm of automation solutions and the latest technology that is propelling the metal and mining industry into a new era of success.

Enhancing Efficiency and Productivity

Automation services, enabled by PLCs, DCS, SCADA, and HMIs, offer metals and mining companies unprecedented opportunities to enhance efficiency and increase productivity. PLCs serve as the backbone of automation, controlling and monitoring various processes, such as ore extraction, crushing, and material handling, with precision and reliability. By integrating PLCs with DCS, companies can centralize control and automate complex operations, optimizing resource utilization and reducing downtime.

SCADA systems play a crucial role in real-time monitoring and control. By providing a holistic view of operations, SCADA empowers companies to make data-driven decisions and identify trends, enabling proactive measures to enhance productivity. The integration of HMIs further simplifies the human-machine interaction, allowing operators to monitor and control processes intuitively, thus improving overall efficiency.

Data Management and Analysis

Automation services in metals and mining also encompass advanced data management tools such as Historians. Historians collect and store vast amounts of data generated by automation systems, enabling companies to gain valuable insights and drive informed decision-making. With Historians, metals and mining companies can analyse historical data, identify trends, and optimize processes for maximum efficiency.

By utilizing data analytics techniques, such as machine learning and predictive modelling, companies can unlock hidden patterns and correlations within their operational data. This allows for predictive maintenance strategies, optimizing equipment performance, reducing downtime, and maximizing asset lifecycle. Moreover, data analysis enables continuous improvement initiatives, identifying areas for process optimization and resource allocation.

Improving Safety Standards

Safety is a paramount concern in the metals and mining industry. Automation services play a critical role in enhancing safety standards by minimizing human involvement in hazardous areas. Through the integration of automation technologies, such as robotics and remote monitoring systems, companies can ensure the safety of workers while optimizing operations.

Robotic systems, controlled by PLCs and DCS, can handle physically demanding and high-risk tasks, reducing the likelihood of accidents and injuries. SCADA systems enable remote monitoring and control, allowing operators to monitor critical parameters from a safe location. Real-time alerts and alarms further enhance safety, ensuring timely responses to potential hazards.

Streamlining Supply Chain Management

Automation services also extend to streamlining supply chain management in metals and mining companies. Through the integration of automation technologies, such as SCADA and data analytics, companies can optimize inventory management, logistics, and procurement processes.

SCADA systems provide real-time visibility into the supply chain, allowing companies to monitor inventory levels, track shipments, and anticipate demand fluctuations. This enables proactive decision-making, minimizing delays and ensuring timely deliveries. By leveraging data analytics, companies can identify trends in demand, optimize inventory levels, and enhance supply chain efficiency.

Conclusion

Today’s Automation technologies have significantly enhanced efficiency, productivity, safety standards, and supply chain management. As a leading provider of automation solutions in the metals and mining sector, Parijat Controlware, Inc. has played a pivotal role in empowering companies with tailored automation services. Through their expertise and innovative solutions, Parijat Controlware, Inc. has helped metals and mining companies optimize their processes, improve safety measures, and make data-driven decisions. With their comprehensive suite of automation services, Parijat Controlware, Inc. has successfully enabled companies in the metals and mining industries to achieve operational excellence and sustainable growth.