Parijat HMI/SCADA Open-source Development System

Microsoft VB.NET Configurable, scalable, maintainable

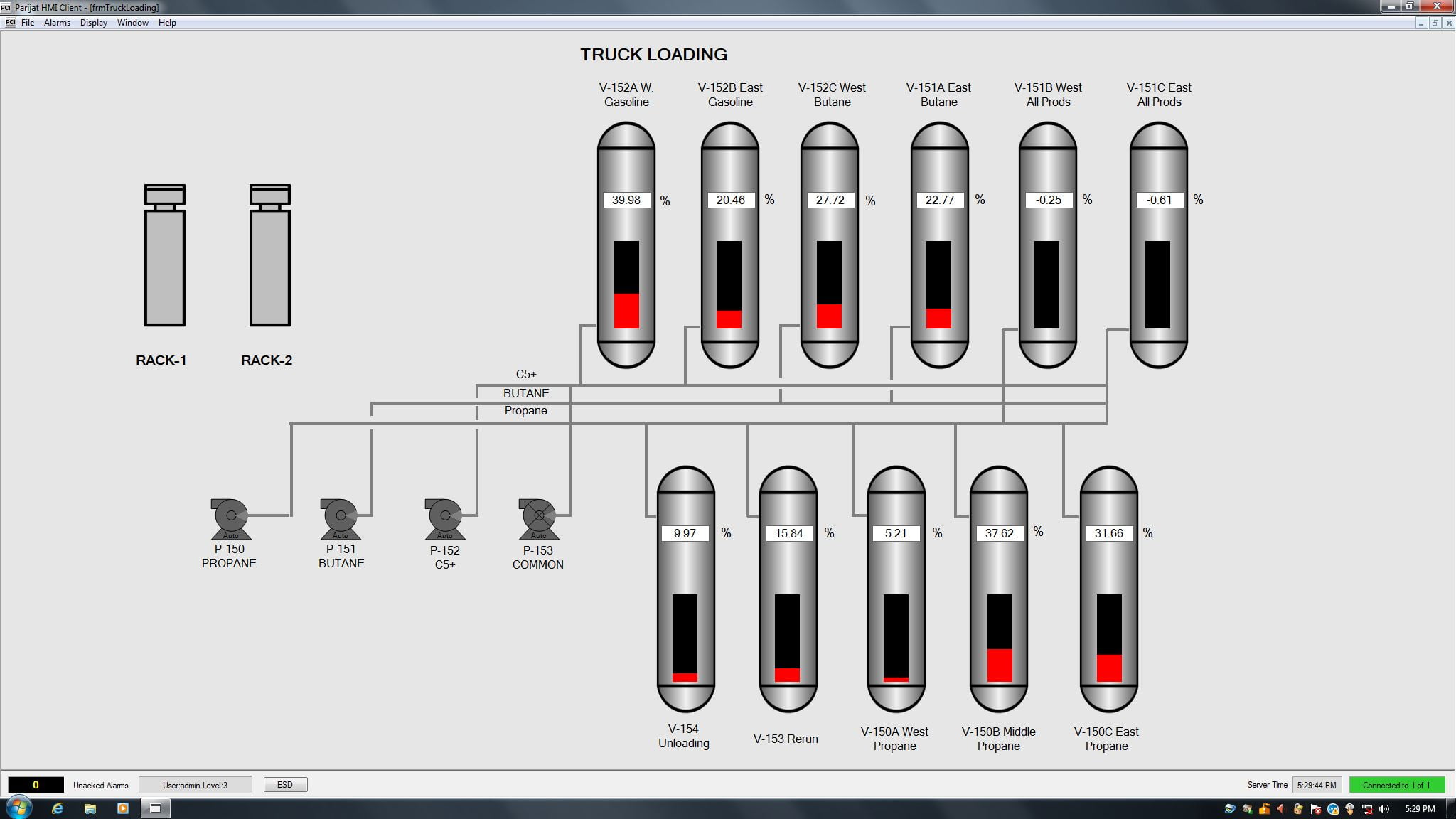

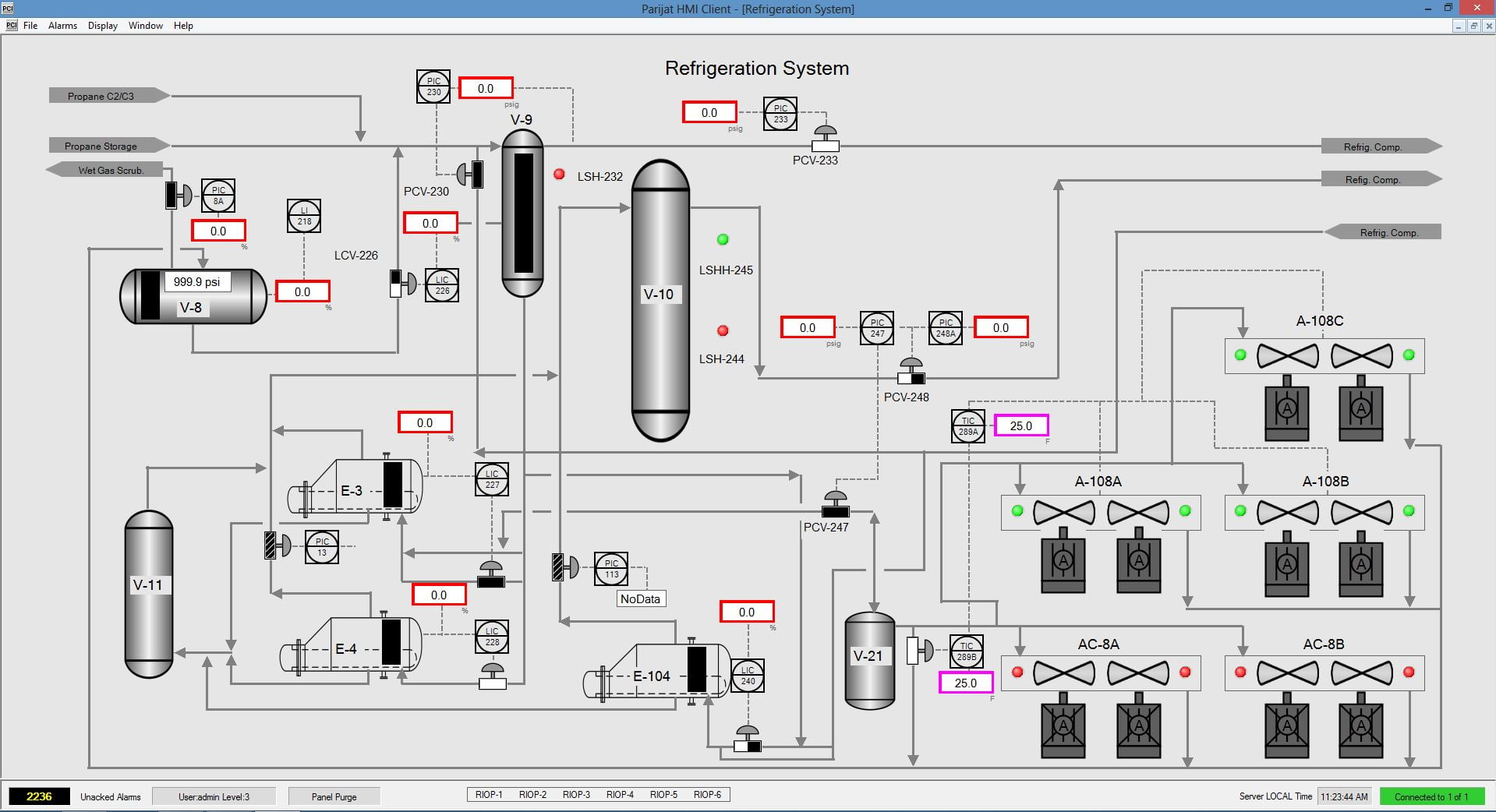

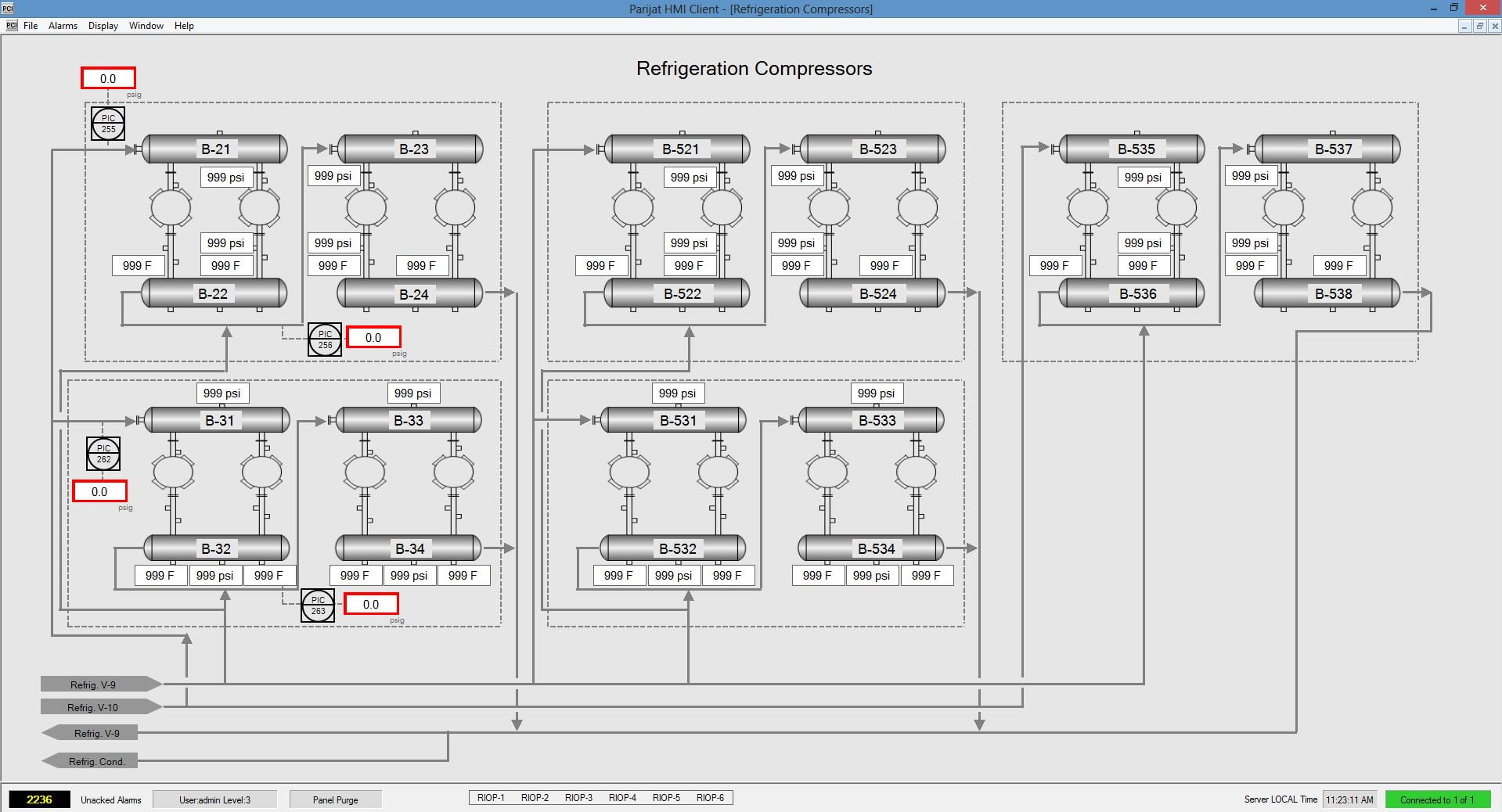

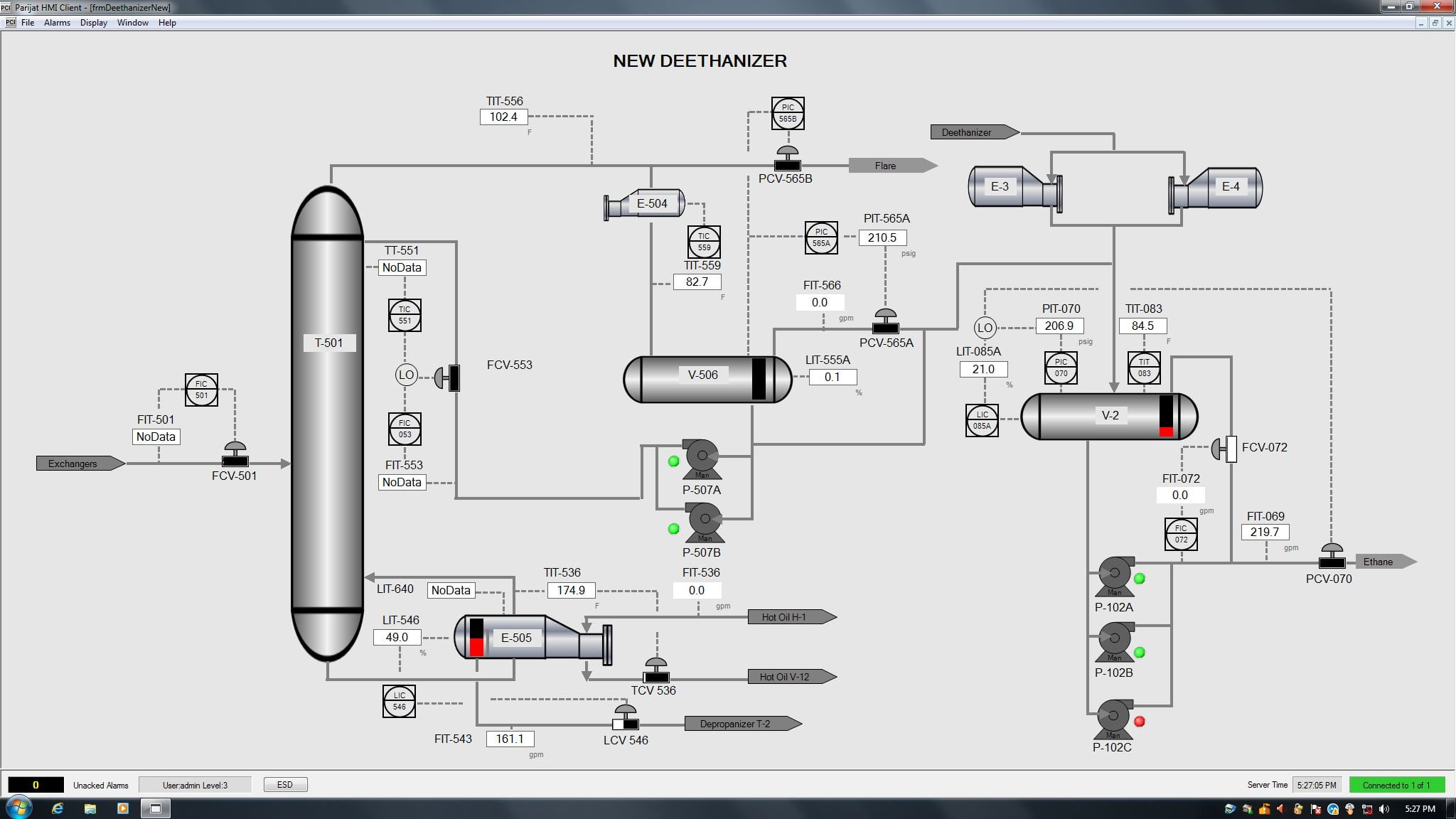

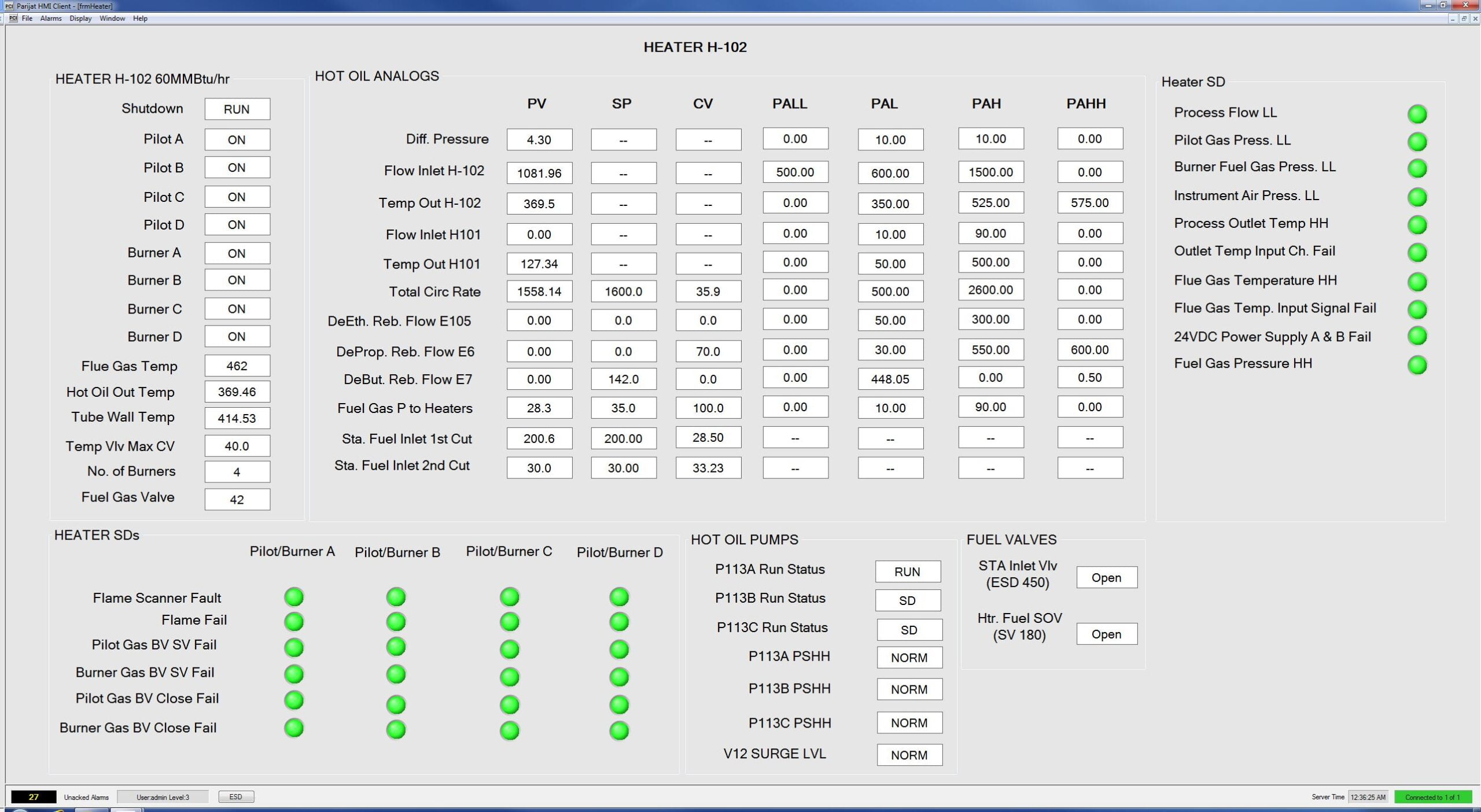

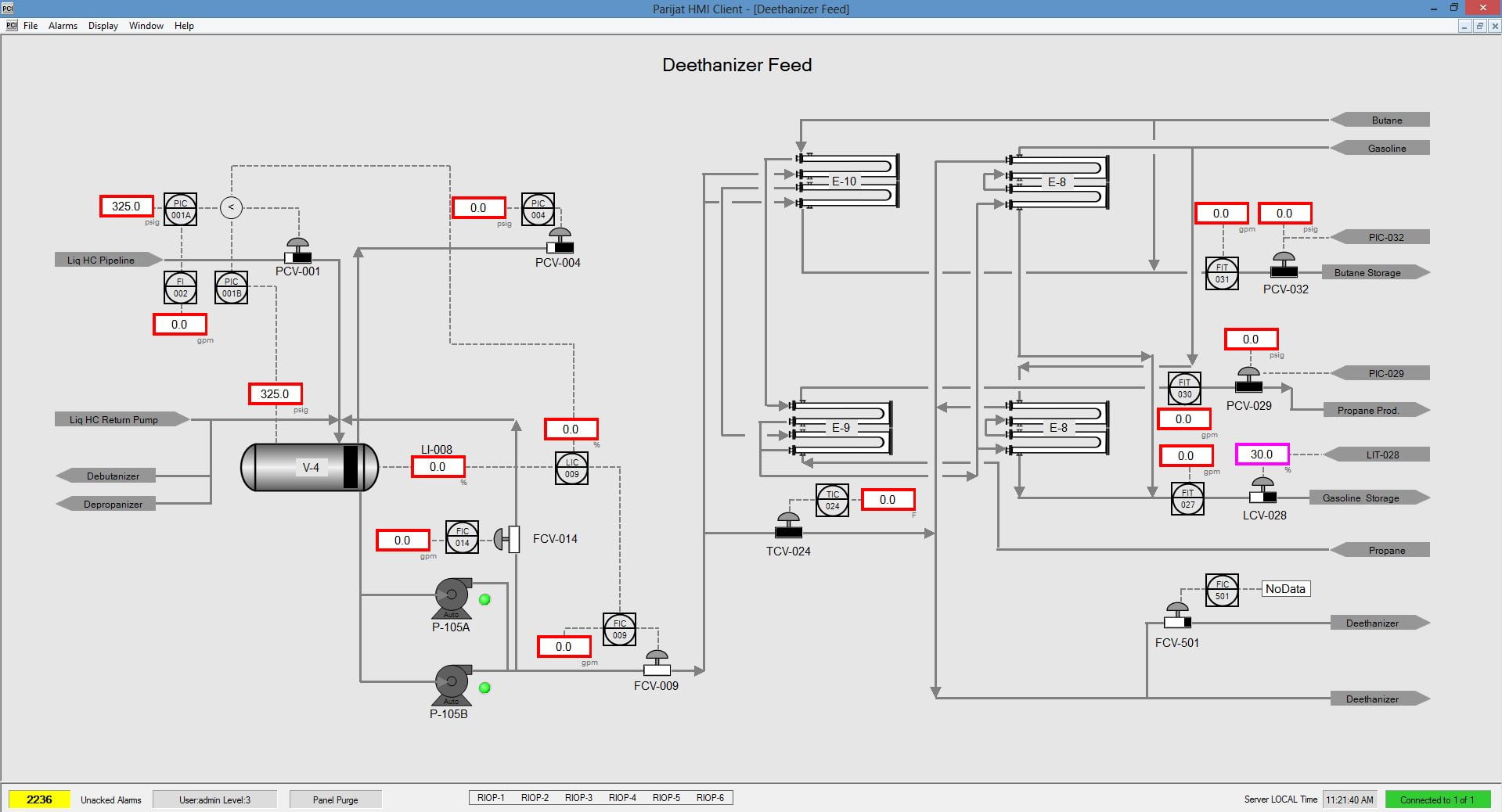

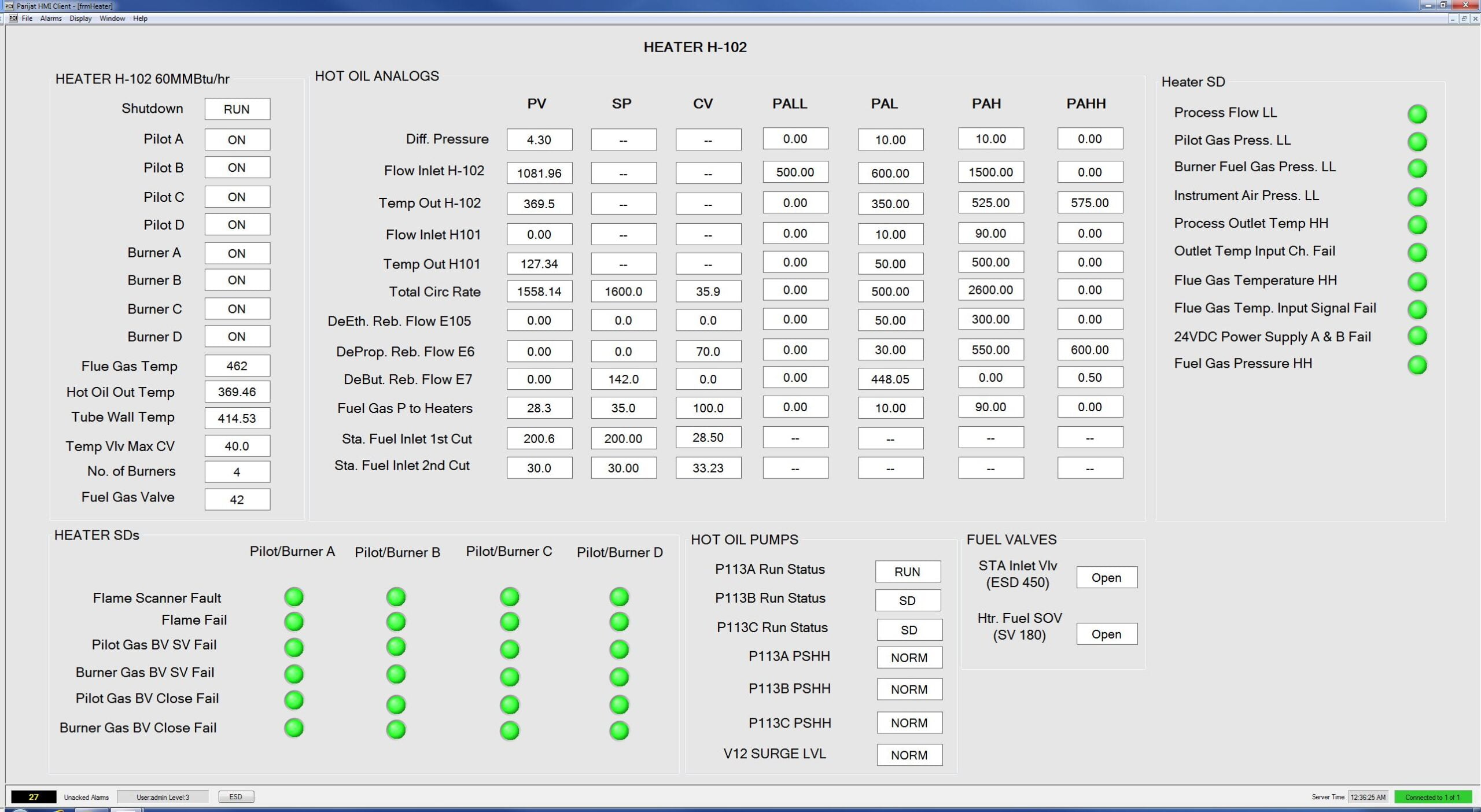

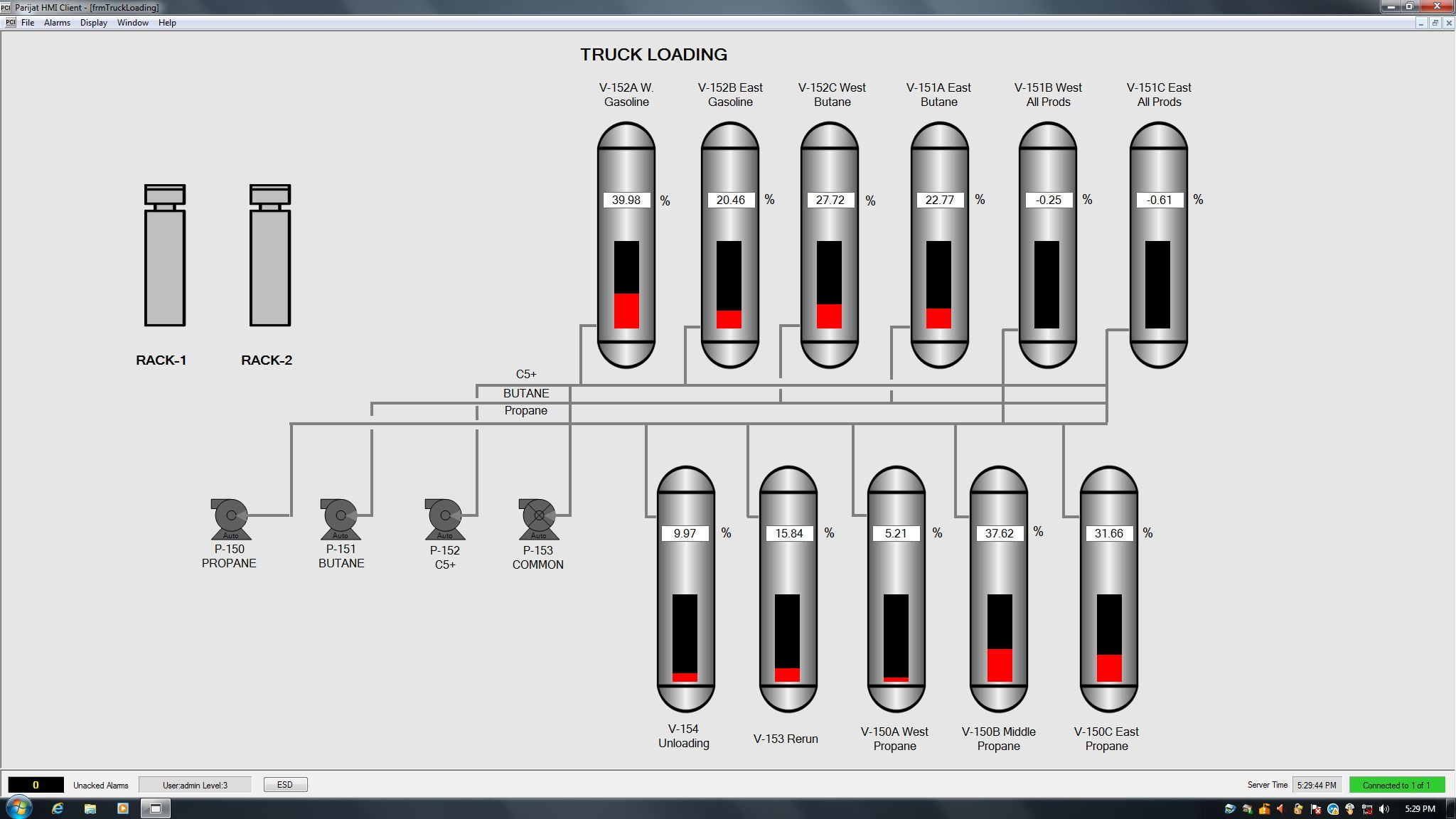

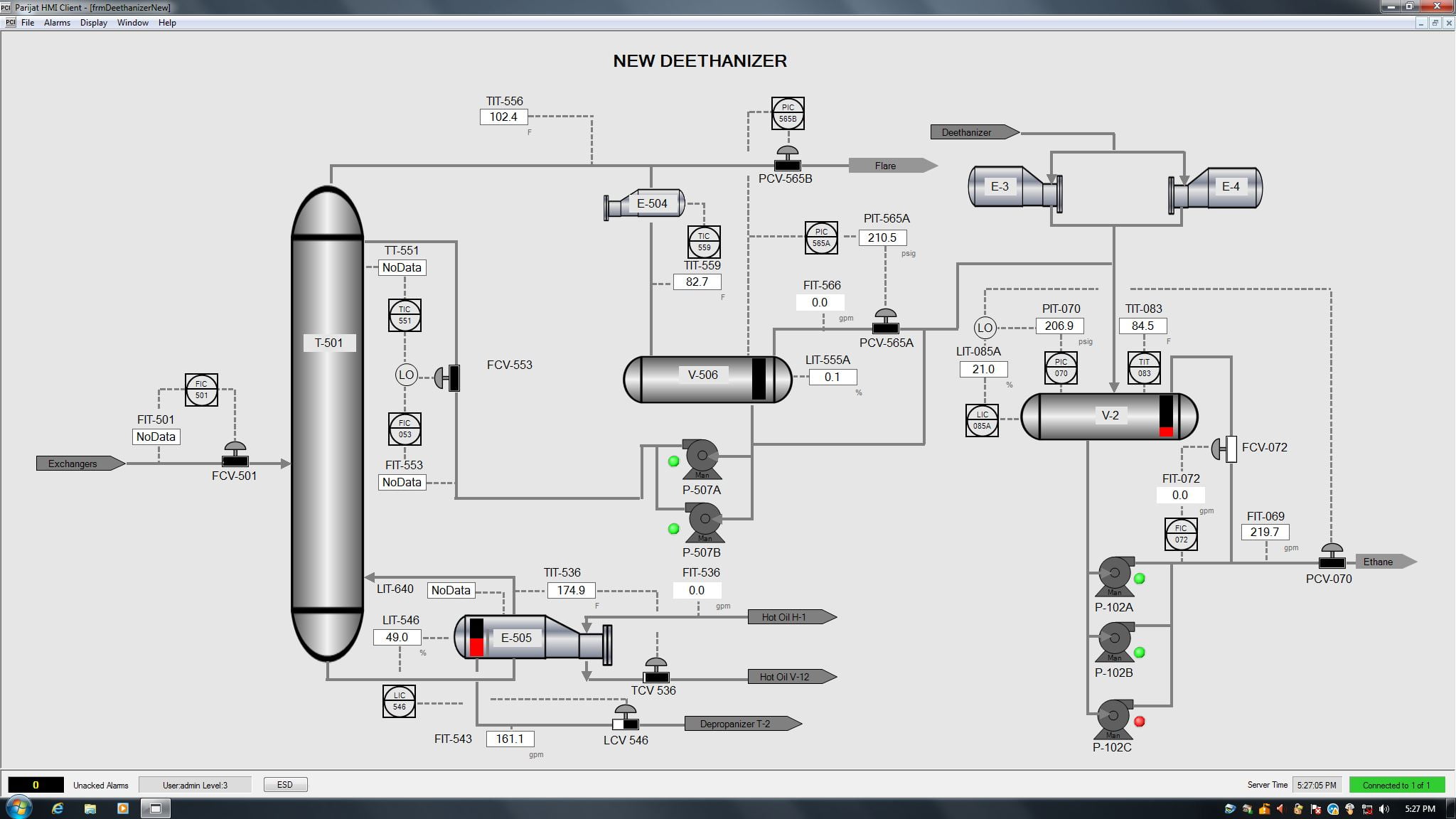

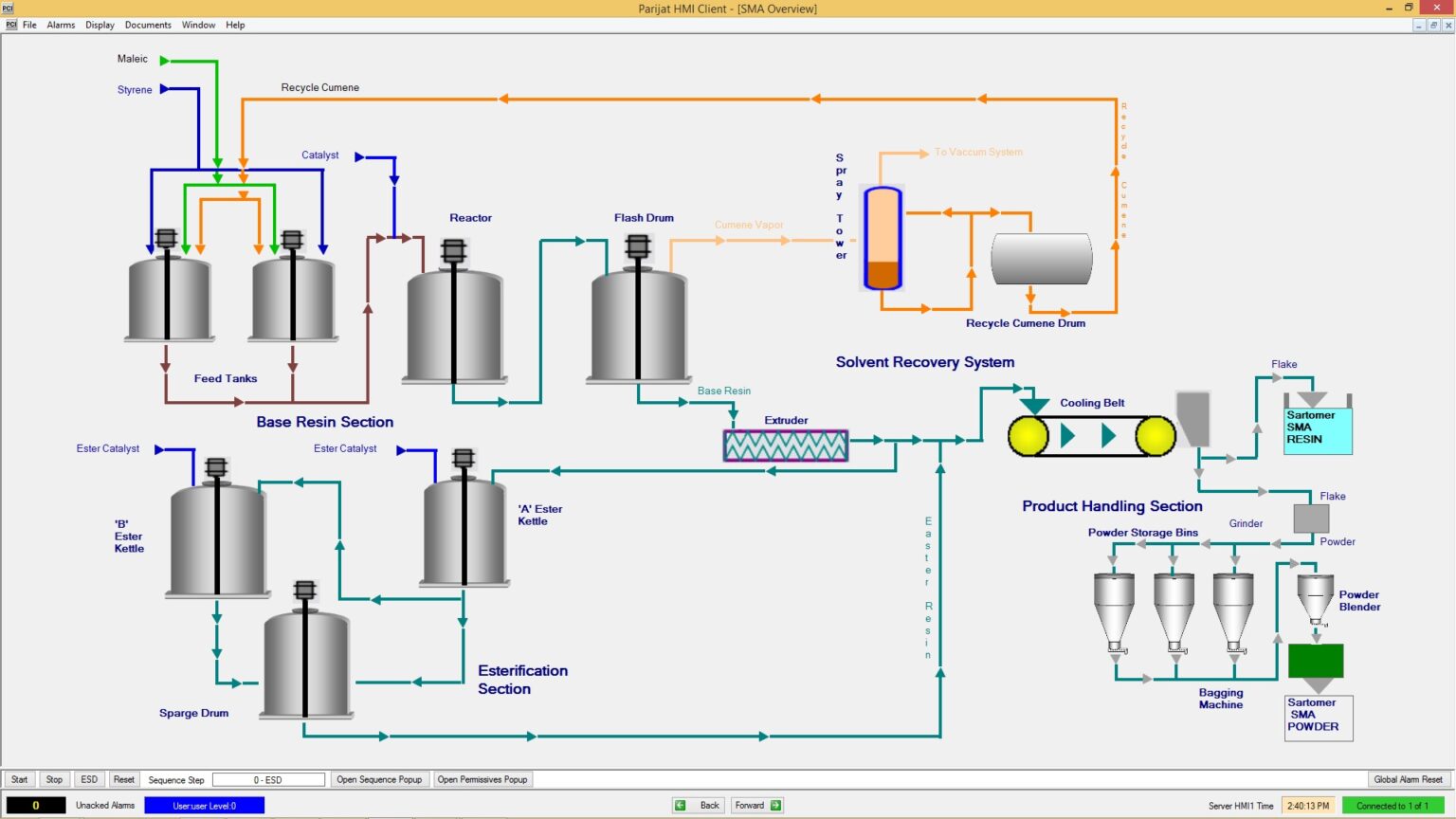

This product was developed under Microsoft Visual Basic.NET for Desktop Windows environment. It lets you rapidly build full-featured Human Machine Interface (HMI) or SCADA systems for any applications. It can also be used to create any HMI for SCADA to PLC, DCS, Flow Computers, Chromatographs, and/or any system where data needs to be reported in a tabular/graphical format, or a GUI to database system. This development rivals proprietary non-Microsoft products like Intouch from Wonderware, iFix DMACS from GE-Intellution, RSView32 from Rockwell-AB, USData Factorylink, Citect, Genesis and provides the configurability, scalability, and maintainability so that individuals with minimum exposure to VB can quickly master and build HMI applications.

If you are using proprietary/legacy HMI or SCADA products from companies other than Microsoft, and are having problems with the configurability as well as their licensing policies, costs, support delays and limitations then Parijat has an open-source solution for you.

What does the Parijat HMI do for my HMI/SCADA?

Define the points/tags to read/write using a GUI & store the configuration in a pre-built MSDE or MS SQL server DB table. Enter appropriate data for trending, alarming, limits and scaling.

Select as many of the pre-built PLC communication drivers as needed for your application. Create HMI Display Forms: You just need to copy the sample Form from the template (examples provided). Drop your required VB controls on it, making the display suiting your application. Then, with the Parijat Control Wizard “link” a VB control (Label, Textbox, Picturebox, and other controls) to a reference address in the PLC data (word or bit). Via this control wizard the user may also specify different types of animation configurations for this VB control. The configuration is stored in the .Tag property of the control.

The control Tag property may also be set independently to provide different display/form-specific configurations without the wizard.

At run time of VB, the controls for which the properties were defined at configuration time start automatically updating if this form is loaded. No VB coding is necessary.

Features

- It is a typical VB standard executable project. No run-time royalties.

- Support for about 40 industrial communication protocols (more being continuously developed).

- Designed to make use of the fast throughput and exception based processing of VB.NET

- Unlimited points (Tags of the conventional HMI world) and displays.

- Powerful animation and various Windows graphical file support.

- Does NOT limit you from using any other capabilities of VB in any way. Use any 3rd party controls.

- Make any changes to points/tags without stopping the polling, data storage.

- Designed for field personnel, who are not VB programmers. For HMI screen modifications, no VB code needs to be written.

- Uses Microsoft SQL server (MSDE via ADO.NET) without the overhead of ODBC. Or using ODBC, any ODBC compliant database.

- Configure HMI displays by setting properties of Microsoft or use 3rd party controls. If chosen.

- Configurable scanning of foreign smart devices like PLCs, DCS. Flow meters and so forth.

- Can be an OPC server or OPC client. (When using OPC, the project becomes non managed)

- No multi-sourcing, no need to have multiple applications from multiple non-Microsoft vendors.

- Integrate ALL the business system needs and the HMI into ONE single application.

- Very powerful alarming and trending capabilities (up to 32 pens at the same time).

- Complicated Communication & screen update issues are resolved.

- Several pre-built symbols provided. You may create your own or buy third-party symbols in standard BMP, JPG, GIF, etc. formats.

- Redundant server capability without expensive clustering hardware or licenses.

- Technology Transfer services is available from Parijat.

- Leverages Microsoft’s research in software development.

- One could also use VB to publish real time data over the Internet via ASP.NET or other Internet technologies and build server-side/client-side applications.

Product Components

Define the points/tags to read/write using a GUI & store the configuration in a pre-built MSDE or MS SQL server DB table. Enter appropriate data for trending, alarming, limits and scaling.

- Select as many of the pre-built PLC communication drivers as needed for your application.

- A .NET service or desktop app running as a server, responsible for communication with field devices, alarms and historians

- A .NET client application for creating the user display forms, and animations of VB objects (Source Code provided).

- An MSDE database structure, schema for data population, specific to your application of HMI/SCADA. A front-end editor utility is provided. Or use any tools for MS SQL Server edits.

- A Parijat control wizard to help edit the .TAG property of animated controls.

Minimum Requirements

- Microsoft Visual Basic .NET Community Edition or better

- Microsoft Windows 7 with SP1 or later

- Microsoft SQL Server Express Edition

- 2GB RAM (Higher configurations needed if applying systems with > 500 points)

- 10GB of Free Disk Space

- Use of one or more Parijat communication drivers.

Options

Define the points/tags to read/write using a GUI & store the configuration in a pre-built MS SQL server DB table. Enter appropriate data for trending, alarming, limits and scaling.

- Source Code for the MSDE Config utility.

- Source Code for the HMI Server .NET application.

- HMI Parijat Control wizard and/or its Source Code.

- Multi-client application update utility

- New driver or scanner applications