Introduction

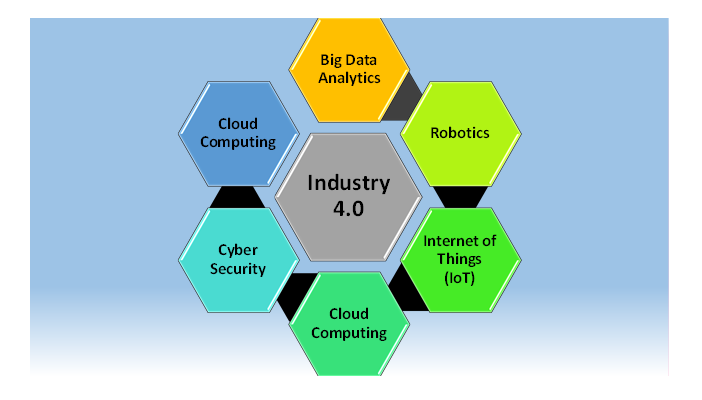

The marine industry is undergoing a significant transformation, driven by the latest advancements in automation technologies. From robotics and artificial intelligence (AI) to the Internet of Things (IoT) and machine learning, these cutting-edge solutions are revolutionizing the way ships, ports, and offshore facilities operate. In this article, we will explore the latest technical trends in automation and their profound impact on the marine industry

Integration of Robotics and AI

The integration of robotics and AI is revolutionizing the marine industry. Autonomous robots are being deployed for tasks such as cargo handling, inspection, and maintenance. These robots can navigate complex environments, perform repetitive tasks with precision, and reduce the need for human intervention in hazardous or remote areas. AI-powered algorithms analyse data from various sensors to optimize operations, enabling ships and ports to achieve higher levels of efficiency, productivity, and safety.

Robotic systems equipped with AI capabilities have transformed cargo handling operations in ports. Automated cranes and robotic arms can efficiently load and unload containers, ensuring fast and accurate cargo movement. AI algorithms can also analyse historical data to optimize container placement on ships, maximizing space utilization and minimizing transportation costs. The integration of robotics and AI in cargo handling processes has significantly enhanced productivity and streamlined logistics in the marine industry.

Leveraging IoT for Real-time Monitoring

The Internet of Things (IoT) is playing a crucial role in real-time monitoring and control within the marine industry. Sensors embedded in equipment, machinery, and infrastructure collect vast amounts of data, enabling comprehensive monitoring of critical parameters. IoT platforms gather and analyze this data, providing insights for proactive decision-making and predictive maintenance. With real-time monitoring, potential failures can be identified in advance, minimizing downtime, optimizing maintenance schedules, and reducing costs.

IoT-enabled sensors installed in various components of a ship or offshore facility provide real-time data on factors such as temperature, pressure, vibration, and fluid levels. This data is transmitted to a central monitoring system, where AI algorithms analyze it to detect anomalies or deviations from normal operating conditions. By leveraging IoT and AI, operators can identify potential issues before they escalate, allowing for timely maintenance or repair actions. This predictive maintenance approach improves equipment reliability, reduces unscheduled downtime, and extends the lifespan of critical assets.

Machine Learning for Predictive Analytics

Machine learning algorithms are transforming how the marine industry manages vast amounts of data. By analysing historical and real-time data, machine learning models can predict equipment performance, detect anomalies, and recommend optimal operational strategies. These predictive analytics enable marine operators to make data-driven decisions, optimize fuel consumption, enhance maintenance practices, and improve overall operational efficiency. Machine learning also facilitates route optimization, considering factors such as weather conditions, traffic, and fuel efficiency.

Machine learning algorithms analyze historical data on vessel routes, fuel consumption, and weather patterns to identify the most fuel-efficient routes. These algorithms continuously learn and adapt based on new data inputs, improving their accuracy over time. By optimizing routes, vessels can reduce fuel consumption, decrease greenhouse gas emissions, and achieve cost savings. Machine learning also helps in predicting equipment failures by identifying patterns in sensor data, allowing for proactive maintenance interventions, and avoiding costly breakdowns.

Automation for Enhanced Safety

Automation technologies are enhancing safety measures within the marine industry. Advanced monitoring systems, combined with AI and machine vision, enable the detection of potential hazards and immediate response to abnormal conditions. Automated safety protocols, including fire detection, leak detection, and collision avoidance systems, minimize risks and protect personnel, vessels, and the environment. Additionally, automation assists in emergency response planning and evacuation procedures, ensuring swift and effective action during critical situations.

Automation technologies such as AI-based video analytics systems and thermal imaging cameras enable real-time monitoring of vessel operations. These systems can detect potential safety hazards, such as unauthorized access to restricted areas or the presence of hazardous materials. AI algorithms can analyze video feeds to identify safety violations or unusual activities, triggering alerts for immediate action. By automating safety protocols and leveraging AI for real-time monitoring, the marine industry can enhance safety standards, mitigate risks, and protect human lives and the environment.

Sustainable Practices through Automation

Automation technologies are instrumental in promoting sustainability in the marine industry. Smart energy management systems optimize power consumption, monitor fuel efficiency, and minimize greenhouse gas emissions. Automated waste management systems streamline disposal processes, ensuring compliance with environmental regulations. Furthermore, automation enables the integration of renewable energy sources, such as solar and wind power, into marine operations, reducing dependence on fossil fuels and promoting eco-friendly practices.

Automation solutions can optimize the use of energy on ships and offshore facilities by monitoring and controlling power consumption. Smart sensors and AI algorithms analyze energy usage patterns, adjust power distribution, and identify energy-saving opportunities. By integrating renewable energy sources into the power systems, such as solar panels or wind turbines, ships and ports can reduce their carbon footprint and achieve sustainability goals. Automated waste management systems monitor and control waste disposal processes, ensuring proper treatment and disposal while minimizing the impact on the environment.

Conclusion

The marine industry is witnessing a revolution fuelled by the latest automation technologies. The integration of robotics, AI, IoT, and machine learning is reshaping operations, from cargo handling and maintenance to safety and sustainability practices. Parijat Controlware’s commitment to delivering innovative automation solutions positions them as a leading provider in the marine industry. Embracing these technological trends is essential for organizations seeking to thrive in a rapidly evolving landscape, ensuring operational excellence and driving the industry towards a more efficient, safe, and sustainable future.

Parijat Controlware is driving the adoption of the latest automation technologies in the marine industry. They offer comprehensive solutions that leverage robotics, AI, IoT, and machine learning to optimize marine operations. Parijat Controlware’s expertise extends to advanced control systems, autonomous robotics, predictive maintenance platforms, and IoT-based monitoring solutions. Their services empower marine industry players to embrace automation, enhancing efficiency, safety, and sustainability while gaining a competitive advantage in the market.