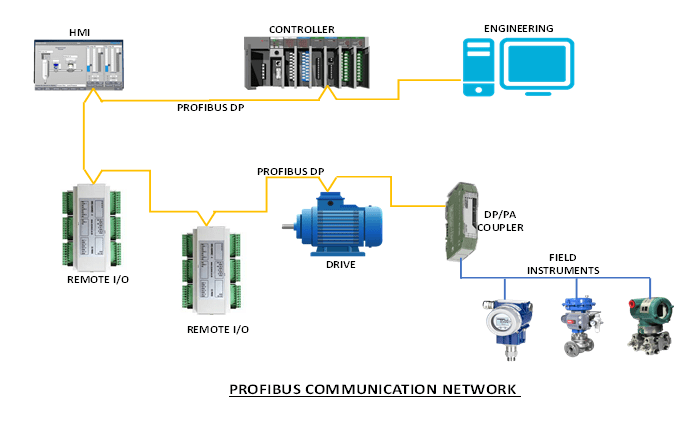

PROFIBUS (Process Field Bus) is a popular industrial communication network used in manufacturing and process automation. It was developed in the late 1980s and has since become a widely used standard for communication between control devices, such as programmable logic controllers (PLCs), drives, sensors, and other automation equipment. PROFIBUS offers high data transfer rates, ranging from 9.6 Kbps to 12 Mbps, and supports a wide range of applications, including process control, motion control, and sensor/actuator networks. It also supports multiple communication protocols, such as DP (Decentralized Peripherals), FMS (Fieldbus Message Specification), and PA (Process Automation).PROFIBUS is highly flexible and can be easily integrated into existing control systems, making it a popular choice for modern industrial automation projects.

Parijat Controlware. Inc (PCI) PROFIBUS based system

For industrial applications, PCI is a premier vendor of PROFIBUS-based automation systems. PROFIBUS, also known as Process Field Bus, is a widely used industrial communication network that is designed to provide fast and reliable communication between control devices in a manufacturing or process automation environment.

PCI has extensive experience in developing and deploying PROFIBUS based systems that can meet the specific needs of various industrial applications. Their solutions are designed to ensure high levels of performance and reliability, as well as providing a high level of flexibility and integration with existing control systems.

PCI PROFIBUS based systems can handle real-time communication and process control. This helps to ensure high levels of accuracy and reliability in demanding industrial environments, making them ideal for use in applications such as motion control, process control, and sensor/actuator networks. PCI also provides a range of support and maintenance services to help customers ensure the optimal performance and reliability of their automation systems. This includes training, technical support, and software updates, ensuring that customers have access to the latest technology and expertise.

PCI offered PROFIBUS Based Systems Key Features

PCI offers PROFIBUS based systems with a range of key features that set them apart from other solutions on the market. Some of the key features include:

1. High Performance: PROFIBUS based systems are designed to provide fast and reliable communication, ensuring high levels of performance in real-world industrial environments.

2. Real-time Communication and Process Control: The systems are capable of handling real-time communication and process control, helping to ensure high levels of accuracy and reliability in demanding applications.

3.High Flexibility: PROFIBUS based systems are highly flexible and can be easily integrated into existing control systems, making them ideal for modern industrial automation projects.

4.Multiple Communication Protocols: The systems support multiple communication protocols, such as DP (Decentralized Peripherals), FMS (Fieldbus Message Specification), and PA (Process Automation), providing a high level of flexibility and integration with different control devices.

5. Support and Maintenance Services: PCI also provides a range of support and maintenance services to help customers ensure the optimal performance and reliability of their automation systems. This includes training, technical support, and software updates.

6.Cost-Effective: PCI PROFIBUS based systems are designed to be cost-effective, providing a high level of performance and reliability at a competitive price.

PCI PROFIBUS based systems a reliable and cost-effective solution for industrial automation applications, providing high performance, flexibility, and a high level of integration with existing control systems.

Conclusion

PCI PROFIBUS based control systems are a reliable and cost-effective solution for industrial automation applications. With their high performance, real-time communication and process control, high flexibility, and support for multiple communication protocols, they provide a high level of accuracy and reliability in demanding industrial environments. Additionally, PCI commitment to customer support and maintenance services ensures that customers have access to the latest technology and expertise to help maintain the optimal performance and reliability of their automation systems. If you are looking for a PROFIBUS based control solution, PCI is a trusted and experienced provider that you can rely on.